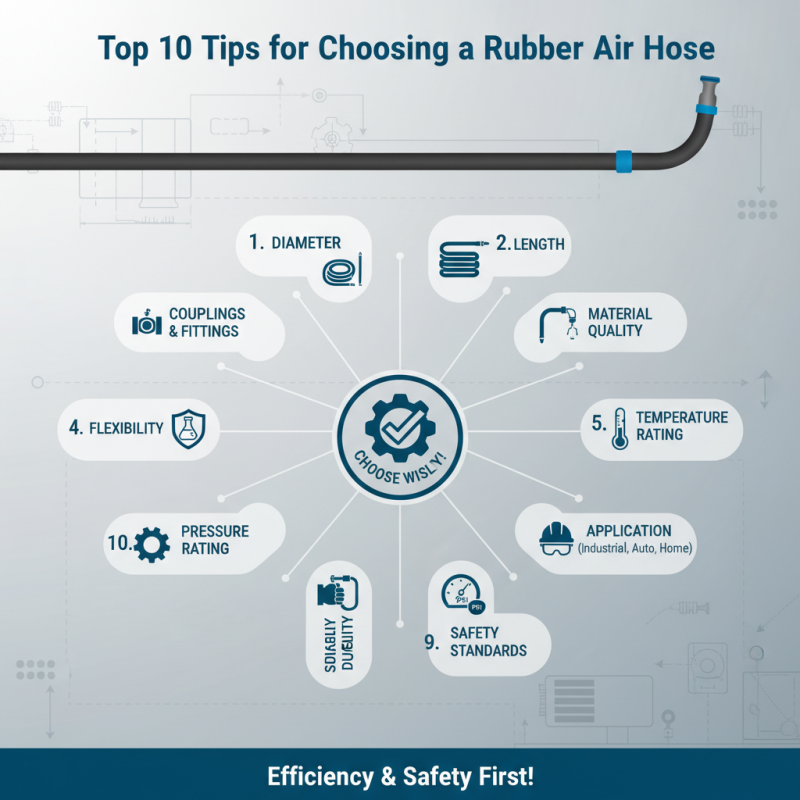

Top 10 Tips for Choosing a Rubber Air Hose?

Choosing the right rubber air hose is essential for efficient and safe applications. Many overlook details when selecting a hose, leading to issues down the road. A rubber air hose must fit your specific needs, whether for industrial, automotive, or home use.

One key factor is the hose's diameter. It influences airflow and pressure handling. Many users wrongly assume all hoses are created equal. Length also matters; a longer hose may reduce pressure. Don’t forget about flexibility; a stiff hose can be difficult to maneuver, limiting its effectiveness.

Material quality plays a significant role. Some rubber hoses can degrade quickly, particularly in harsh environments. Users might choose low-cost options, but these can lead to safety hazards. Remember to consider temperature ratings as well. Ignoring these factors can result in unwanted consequences.

Understanding the Importance of a Quality Rubber Air Hose

When it comes to air hoses, quality really matters. A good rubber air hose enhances performance. It can withstand high pressure and fluctuating temperatures. This durability helps mitigate wear and tear. With regular use, low-quality hoses can leak or burst. These failures often lead to costly repairs or setbacks in projects.

Purchasing the right air hose can be confusing. Not every hose is designed with the same standards. Some are synthetic, while others are pure rubber. Pure rubber hoses generally last longer and can handle extreme conditions. However, they can be heavier and more expensive. Users often overlook these differences. They might choose a cheaper option, which could cost more in the long run.

Understanding the importance of a quality rubber air hose is crucial. It is not just about the price tag. Consider the intended use. Will you be using it outdoors or in a garage? A hose's flexibility is also important. If it's stiff, it may not perform well. Users should ask themselves if they value convenience over durability. This reflection is key to making the right choice.

Key Factors to Consider When Selecting a Rubber Air Hose

When selecting a rubber air hose, consider durability. A robust hose can withstand wear and tear. Look for hoses designed for heavy usage. They should resist abrasions, cuts, and chemicals. This is especially important in industrial settings. A longer-lasting hose saves you money in the long run.

Next, evaluate the size and length. The diameter should match your equipment needs. A hose that's too small can restrict airflow. Similarly, the length should allow for your working environment. A hose that's too short limits mobility, while an excessively long hose may weigh you down.

Flexibility is also crucial. A stiff hose can be difficult to maneuver. You want something that bends easily without kinking. Test the hose's flexibility before purchasing. The color and texture might also influence your choice. Choose something with good visibility for safety. Remember, not every option out there will suit your needs perfectly. Reflect on your specific requirements before making a decision.

Different Types of Rubber Air Hoses and Their Applications

When selecting a rubber air hose, understanding different types is crucial. There are mainly three types: general-purpose, heavy-duty, and specialty hoses. General-purpose hoses are favored for standard tasks. They are lightweight and flexible, making them easy to handle in various settings. Heavy-duty hoses withstand higher pressure and harsh conditions. They're essential for industrial applications where durability is key.

Specialty hoses include those designed for particular environments, like oil-resistant hoses in automotive industries. Research indicates that using the right type increases efficiency by up to 30%. Many professionals underestimate the importance of choosing the correct hose type.

Consider a few tips: First, check the hose's PSI rating. It must match your air compressor's output. A mismatch can lead to performance issues or safety risks. Second, assess the hose's length. Longer hoses lead to pressure drops. Ensure it's long enough for mobility but not excessive. Lastly, think about diameter. A wider diameter allows for larger airflow but may be bulkier. Reflecting on these points can save time and improve productivity in projects.

Top 10 Tips for Choosing a Rubber Air Hose

| Tip No. | Tip | Type of Rubber Hose | Common Applications |

|---|---|---|---|

| 1 | Check the pressure rating | High-pressure rubber hose | Air compressors, pneumatic tools |

| 2 | Consider the hose diameter | Standard rubber hose | General air applications |

| 3 | Evaluate flexibility | Flexible rubber hose | Tight spaces, maneuverability |

| 4 | Look for abrasion and weather resistance | Abrasion-resistant rubber hose | Construction sites, outdoor use |

| 5 | Check for compatibility with fluids | Chemical-resistant rubber hose | Manufacturing environments |

| 6 | Assess temperature ranges | High-temperature rubber hose | Heat-generating equipment |

| 7 | Consider hose length and reach | Custom length rubber hose | Flexible applications |

| 8 | Look for reinforcement layers | Reinforced rubber hose | Heavy-duty applications |

| 9 | Examine fittings and couplings | Hose with quick-connect fittings | Tool connectivity |

| 10 | Determine warranty and durability | Durable rubber hose | Long-term investment |

Evaluating the Durability and Flexibility of Rubber Air Hoses

When choosing a rubber air hose, durability and flexibility are crucial factors. A good hose should withstand harsh conditions. Look for hoses made from high-quality rubber materials. They resist wear and tear, ensuring long-lasting use.

Tip #1: Check the thickness. Thicker hoses often provide better durability. However, too much thickness can hinder flexibility. It’s a balancing act.

Flexibility impacts usability. A hose that kinks easily could cause issues. You want a hose that moves freely without being too rigid. Some hoses excel in cold weather, while others may become stiff.

Tip #2: Assess the temperature range. Hoses should work well in various conditions. Extreme temperatures can affect performance.

Consider the hose's weight, too. Lightweight hoses are easier to maneuver. Yet, some might sacrifice durability for weight. A heavy hose could be tough but may be cumbersome.

Tip #3: Look for added features. Reinforcements can improve durability. Bend restrictors can help prevent kinking. Each feature has its pros and cons. Make informed choices based on your needs.

Safety Features to Look for in a Rubber Air Hose

When choosing a rubber air hose, safety features are crucial. Look for hoses with burst pressure ratings that exceed your equipment's requirements. This ensures they can handle intense pressure without bursting. Always check for certifications that confirm safety standards.

Consider hoses with reinforced layers. These layers help prevent kinks and abrasions. A kink can restrict airflow and lead to damage. Also, a rubber air hose should be lightweight for easy handling. Ease of use promotes safety, especially in busy work environments.

Test flexibility in various temperatures. Hoses that become rigid in cold weather can lead to accidents. Ensure they remain pliable, allowing for smooth maneuverability. Regular inspections are vital too. Small cracks can develop unnoticed, posing risks. Remember, a damaged hose can lead to equipment failure, endangering users and others nearby. Keep a clear focus on these details for a safer experience.