Top 10 Custom Engineering Trends You Need to Know?

The landscape of custom engineering is rapidly evolving. According to the Engineering News-Record, the global engineering market is projected to reach $12 trillion by 2025. This growth highlights the increasing demand for tailored solutions in engineering. Custom engineering plays a critical role in addressing unique client needs. Companies that adapt will thrive.

Emerging trends are driving innovation. For instance, the rise of automation and AI integration is transforming how engineers design and execute projects. A recent report from McKinsey indicates that 70% of companies are already applying AI in their engineering processes. However, this shift raises questions. Are we prepared for the challenges that come with new technologies? As we embrace customization, we must also consider the risk of over-reliance on automated systems.

Sustainability is another pressing theme in custom engineering. According to the Global Engineering Report, 85% of clients prioritize eco-friendly solutions. Engineers are tasked with creating designs that are both functional and sustainable. Yet, balancing client demands with environmental considerations remains a complex challenge. Custom engineering must navigate these waters carefully to ensure a sustainable future.

Emerging Technologies Shaping Custom Engineering in 2023

Emerging technologies are dramatically shaping the landscape of custom engineering in 2023. Automation and robotics are at the forefront. According to a recent industry report, 70% of engineers are adopting these technologies to enhance productivity. Automated systems can significantly reduce production time, but they also pose new challenges. Training staff to operate complex machinery has become essential.

Artificial Intelligence (AI) is another transformative force in this field. Today, AI algorithms predict project outcomes with 85% accuracy. This helps in making informed decisions, but reliance on AI can sometimes lead to unforeseen issues. Engineers may find themselves second-guessing their instincts. It's a delicate balance between intuition and data-driven conclusions.

Sustainability remains a critical concern. The push for eco-friendly designs is more than just a trend; it is a necessity. Reports indicate that 60% of custom engineering projects now incorporate sustainable materials. While this shift is promising, finding the right balance between cost and sustainability is not straightforward. The industry must navigate these complexities as it embraces technological advancements.

Top 10 Custom Engineering Trends You Need to Know - Emerging Technologies Shaping Custom Engineering in 2023

| Trend | Description | Impact | Expected Growth |

|---|---|---|---|

| Artificial Intelligence | Integration of AI for automated design processes and predictive maintenance. | Increased efficiency and reduced operational costs. | 25% Annual Growth |

| Internet of Things (IoT) | Use of connected devices for real-time monitoring and data collection. | Enhanced decision-making and operational transparency. | 30% Annual Growth |

| Additive Manufacturing | 3D printing for customized parts and rapid prototyping. | Reduced lead times and material waste. | 20% Annual Growth |

| Robotics | Automation of processes using advanced robotic systems. | Increased productivity and precision in manufacturing. | 15% Annual Growth |

| Digital Twin Technology | Creation of real-time digital replicas of physical systems. | Improved performance monitoring and predictive analytics. | 18% Annual Growth |

| Sustainable Engineering | Focus on eco-friendly materials and processes. | Reduction in carbon footprint and waste production. | 22% Annual Growth |

| Cloud Computing | Utilization of cloud services for scalable computing resources. | Flexibility and cost savings on IT infrastructure. | 28% Annual Growth |

| Blockchain in Engineering | Application of blockchain for secure and transparent data sharing. | Enhanced security and traceability in processes. | 12% Annual Growth |

| Augmented Reality (AR) | Use of AR for design visualization and training processes. | Improved user engagement and reduced training time. | 19% Annual Growth |

| Simulation and Modeling | Advanced simulation techniques for testing designs before production. | Cost-effective and risk-reducing design processes. | 17% Annual Growth |

Sustainable Practices in Custom Engineering Design and Production

Sustainable practices are reshaping custom engineering design and production. Many companies are embracing eco-friendly materials. This shift not only reduces waste but also lowers energy consumption. Engineers are exploring recycled metals and biodegradable plastics. Sustainable sourcing is crucial. It supports local economies and minimizes transportation emissions.

Life Cycle Assessment (LCA) is often used to evaluate a product's environmental impact. It's an important tool that helps identify areas for improvement. However, LCA can be complex and time-consuming. Some engineers may overlook its full potential. Transparency in the supply chain is another challenge. It’s difficult to track every material's origin.

Designing for durability is equally vital. Products should last longer, reducing the need for replacements. However, achieving this can be tricky. Balancing cost, functionality, and sustainability requires creativity. Continuous innovation is necessary, yet it can lead to unforeseen issues. Engineers must be reflective, learning from setbacks.

The Role of Artificial Intelligence in Custom Engineering Solutions

Artificial Intelligence (AI) is transforming custom engineering solutions. It enhances design processes, improving precision and efficiency. Engineers can analyze complex data sets quickly. This leads to better-informed decisions. Predictive analytics is a key application. Teams can forecast potential challenges and address them proactively. However, AI can also amplify biases present in training data. It’s vital to remain vigilant.

Another significant application of AI is in automation. Routine tasks can be streamlined. This frees engineers to focus on creative aspects. Yet, reliance on technology raises concerns. What about the human touch? Creativity is essential in engineering. There is a risk that automation may overlook nuanced details. Finding a balance is crucial.

Furthermore, AI aids in real-time monitoring and feedback. Engineers receive instant updates during projects. This allows for rapid adjustments. Yet, constant connectivity can be overwhelming. Teams may face information overload. Managing this flow is essential for success in custom engineering. It’s about leveraging technology while maintaining human insight.

Adaptive Manufacturing Techniques for Personalized Engineering Projects

Adaptive manufacturing techniques are transforming personalized engineering projects. These methods focus on flexibility and efficiency. They allow for rapid changes in design based on customer feedback. This is crucial in today's fast-paced market, where preferences shift quickly.

One innovative approach is the use of 3D printing. It enables the production of custom parts on demand. This not only reduces waste but also saves time. However, quality control remains a challenge. Ensuring that each printed item meets strict standards can be difficult. Teams must create robust testing protocols to address these issues effectively.

Another trend is modular design. Engineers can create components that are interchangeable. This facilitates easy upgrades and repairs. While this approach promotes sustainability, it can complicate logistics. Companies need to manage inventory carefully to avoid shortages. Balancing customization with efficiency is key to successful adaptive manufacturing.

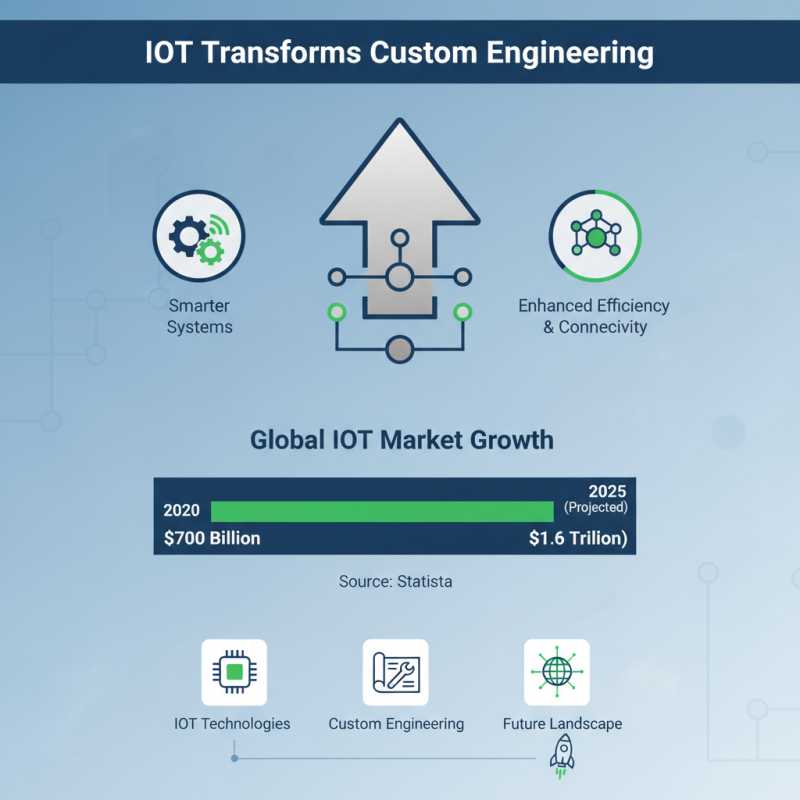

Integrating IoT for Enhanced Custom Engineering Applications

The integration of IoT technologies in custom engineering applications is transforming the landscape. According to a recent report from Statista, the global IoT market is projected to grow to $1.6 trillion by 2025. This surge is pushing engineers to adopt smarter systems that enhance efficiency and connectivity.

Utilizing IoT allows for real-time data collection and analysis. For instance, sensors can predict equipment failures, reducing downtime significantly. A study by McKinsey indicates that IoT could enhance operational efficiencies by up to 30% in certain industries. However, the implementation of these technologies is often met with challenges, such as data security concerns and interoperability issues.

Engineers must also rethink their designs to accommodate IoT features. It’s not just about adding sensors; it’s about creating a cohesive ecosystem. This shift demands attention to user experience and system integration. Every decision can lead to unforeseen complications. The potential for improved performance is immense, but careful planning is crucial. The path to fully leverage IoT in custom engineering contains both opportunities and pitfalls.

Related Posts

-

Revolutionizing Industries with Tailored Custom Engineering Solutions

-

7 Best Air Tech Innovations Transforming Your Home Experience

-

Exploring the Efficiency of Oil Vacuum Pumps: The Future of Industrial Sustainability

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

2026 Best Dry Vacuum Pumps for Efficient Industrial Applications?