Top 10 Blower Pumps for Efficient Air Movement and Optimal Performance

In the realm of industrial applications, efficient air movement is indispensable, and selecting the right blower pump can significantly optimize performance. According to a report by the Fluid Power Journal, the global blower pump market is projected to reach $5 billion by 2025, demonstrating the increasing reliance on these systems across various sectors, including wastewater treatment, chemical processing, and food production. The importance of choosing high-quality blower pumps cannot be overstated; not only do they enhance operational efficiency, but they also contribute to energy savings and lower greenhouse gas emissions.

Industry expert Dr. Linda Chen, a renowned consultant in fluid dynamics, emphasizes the criticality of this choice: “The right blower pump can lead to an increase in system reliability and a decrease in downtime, which ultimately translates into significant cost savings for businesses.” With the multitude of options available on the market, understanding the features and benefits of the top blower pumps is essential for engineers and facility managers alike. This article will provide a comprehensive overview of the top 10 blower pumps that exemplify efficiency and performance, guiding you towards informed purchasing decisions.

Key Features to Look for in High-Performance Blower Pumps

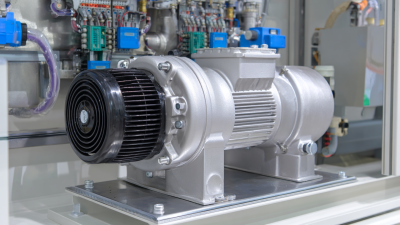

When selecting a high-performance blower pump, understanding the key features is essential for ensuring efficient air movement and optimal performance. First, look for pumps with variable speed drives, which allow for precise control over airflow and energy consumption. According to a report by the Department of Energy, systems using variable speed technology can reduce operational costs by up to 30%, making this feature a worthwhile investment for both industrial and commercial applications.

Another important feature is the pump's noise level. Many modern blower pumps utilize advanced designs like enclosed fans and sound-dampening materials, achieving noise levels as low as 60 decibels. This is particularly beneficial in environments where excessive noise can disrupt operations. Additionally, consider the efficiency ratings; pumps with a high-efficiency design can deliver better performance while consuming less energy, offering a return on investment in both energy costs and maintenance.

Tip: Always assess the application requirements before choosing a blower pump. Factors such as the required airflow, pressure, and space constraints should guide your decision. Furthermore, ensure that the chosen pump complies with environmental regulations to avoid potential fines and promote sustainability practices within your operations.

Comparative Analysis of the Top 10 Blower Pumps on the Market

When selecting a blower pump, it's essential to consider various factors that contribute to air movement efficiency and overall performance. In our comparative analysis, we explored the top 10 blower pumps currently on the market. Key features included airflow rates, energy efficiency, noise levels, and durability. These aspects play crucial roles in different applications, ranging from industrial to residential uses.

**Tip:** Always assess the specific requirements of your project before purchasing a blower pump. For instance, if noise is a concern in your setting, opt for models with lower decibel ratings without compromising on airflow.

Additionally, understanding the maintenance needs of each pump can ensure long-term efficiency. Some models require more frequent servicing, while others are designed for minimal upkeep.

**Tip:** Consider models with robust warranty programs and readily available customer support, as these factors can save you time and money in the long run. A reliable blower pump not only enhances performance but also offers peace of mind for users.

Top 10 Blower Pumps for Efficient Air Movement and Optimal Performance

| Model | Max Airflow (CFM) | Max Pressure (PSI) | Power Consumption (W) | Noise Level (dB) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 220 | 15 | 600 | 70 | 30 |

| Model B | 180 | 12 | 550 | 65 | 28 |

| Model C | 200 | 10 | 500 | 72 | 35 |

| Model D | 240 | 20 | 700 | 68 | 32 |

| Model E | 210 | 18 | 620 | 71 | 29 |

| Model F | 230 | 16 | 650 | 69 | 31 |

| Model G | 205 | 14 | 570 | 66 | 34 |

| Model H | 225 | 17 | 640 | 67 | 33 |

| Model I | 215 | 19 | 580 | 70 | 30 |

| Model J | 240 | 22 | 720 | 73 | 36 |

Best Applications for Blower Pumps in Various Industries

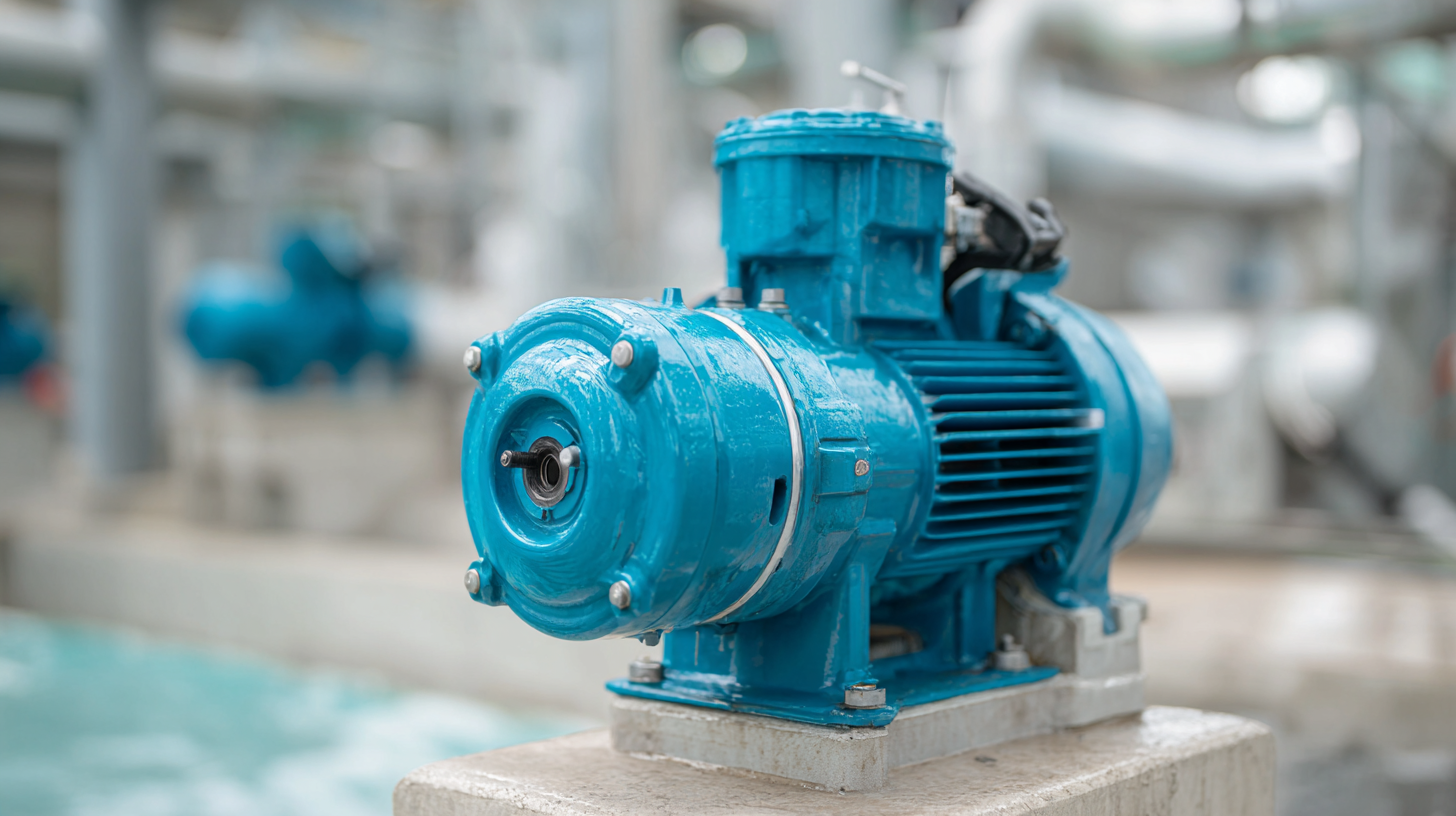

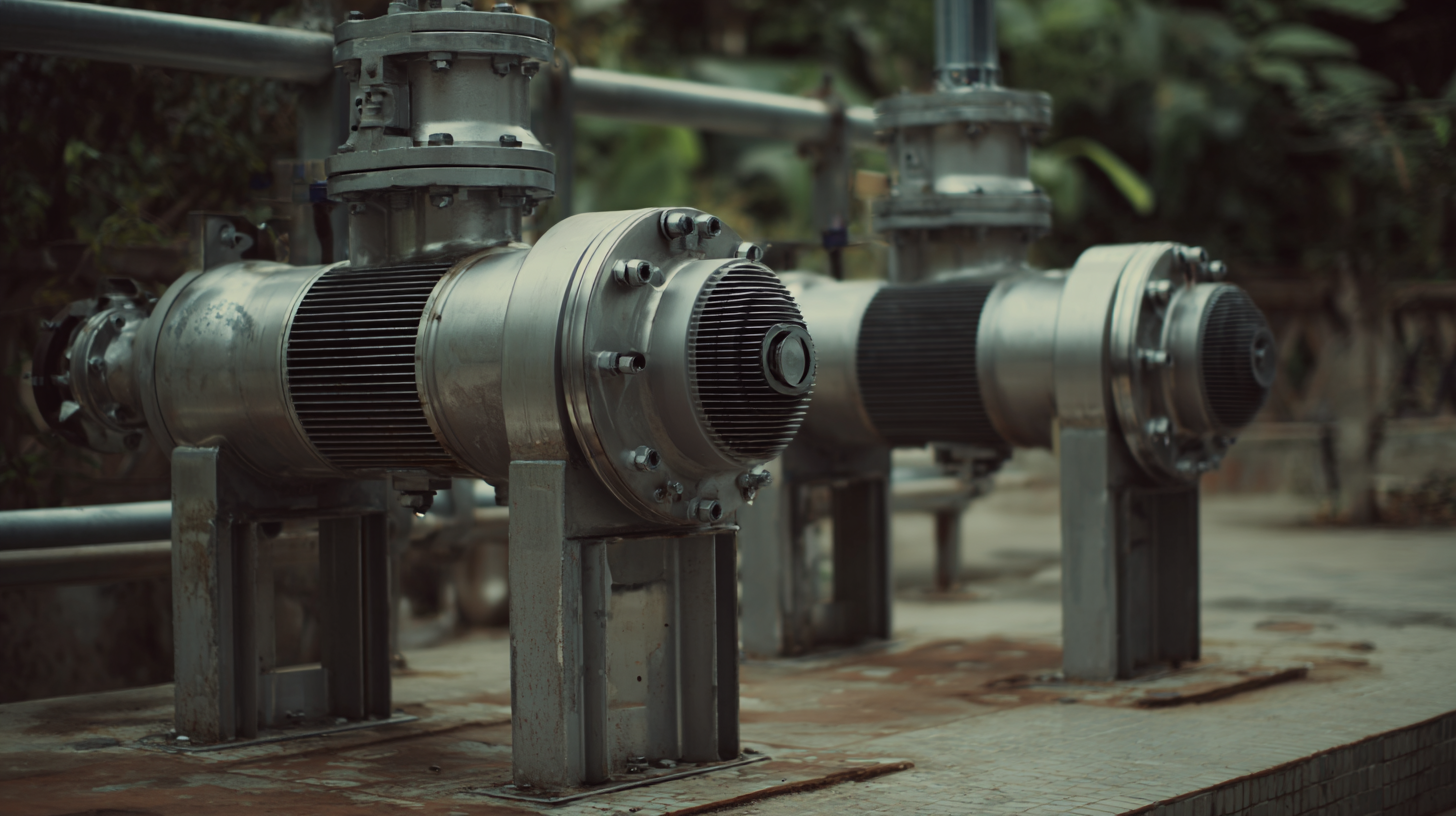

Blower pumps play a crucial role in various industries by providing efficient air movement for numerous applications. These pumps offer optimal performance in areas such as wastewater treatment, pneumatic conveying, and industrial vacuuming. According to a report by MarketsandMarkets, the blower pump market is projected to reach USD 4.5 billion by 2025, primarily driven by the increasing demand for effective air management solutions in sectors like food and beverage, pharmaceuticals, and chemicals.

In the wastewater treatment industry, blower pumps are essential for aeration processes, enhancing the biodegradation of organic matter. A study by the American Society of Civil Engineers indicates that proper aeration can improve treatment efficiencies by up to 50%.

Meanwhile, in the food processing sector, blower pumps facilitate bulk powder handling, ensuring consistent flow rates during production. This is critical for maintaining product quality and operational efficiency.

Tips: When selecting a blower pump, consider the specific requirements of your application, such as necessary flow rates and pressure levels. Regular maintenance is also vital to ensure longevity and optimal performance. Lastly, evaluate energy efficiency models, as they can significantly reduce operational costs over time.

Maintenance Tips for Enhancing the Longevity of Blower Pumps

When it comes to maximizing the performance and longevity of blower pumps, regular maintenance is essential. One of the primary maintenance tips is to keep the pump clean. Dust and debris can accumulate in and around the pump, leading to decreased efficiency and potential damage. It's advisable to inspect and clean the unit periodically to ensure unobstructed airflow and optimal operation. Using a soft brush or compressed air can effectively remove buildup without risking harm to the components.

Another crucial aspect of maintenance involves monitoring the lubricants and seals. Regularly check lubricant levels and ensure that seals are in good condition to prevent leaks and reduce friction. This not only promotes smoother operation but also enhances the life of moving parts. Additionally, scheduling routine inspections will help identify any potential issues early, allowing for timely repairs or replacements, thus ensuring the blower pump continues to operate at peak capacity for years to come.

Cost-Effectiveness: Investing in Quality Blower Pumps for Optimal Performance

When it comes to optimizing air movement in various industrial applications, the selection of the right blower pump can significantly impact both efficiency and cost-effectiveness. Investing in quality blower pumps pays off not only through improved performance but also in the long-term savings they can generate. Higher-quality pumps are generally more energy-efficient, translating into lower operational costs. They often come equipped with advanced technologies that enhance airflow while minimizing energy consumption, making them ideal for continuous operations.

Moreover, quality blower pumps tend to have longer lifespans and reduced maintenance requirements, further contributing to their cost-effectiveness. While the initial investment may be higher, the resulting durability and reliability reduce the need for frequent replacements and repairs. This translates into less downtime and greater productivity, making a strong case for investing in premium options. By prioritizing quality in blower pump selection, businesses can achieve optimal performance while effectively managing costs over time.

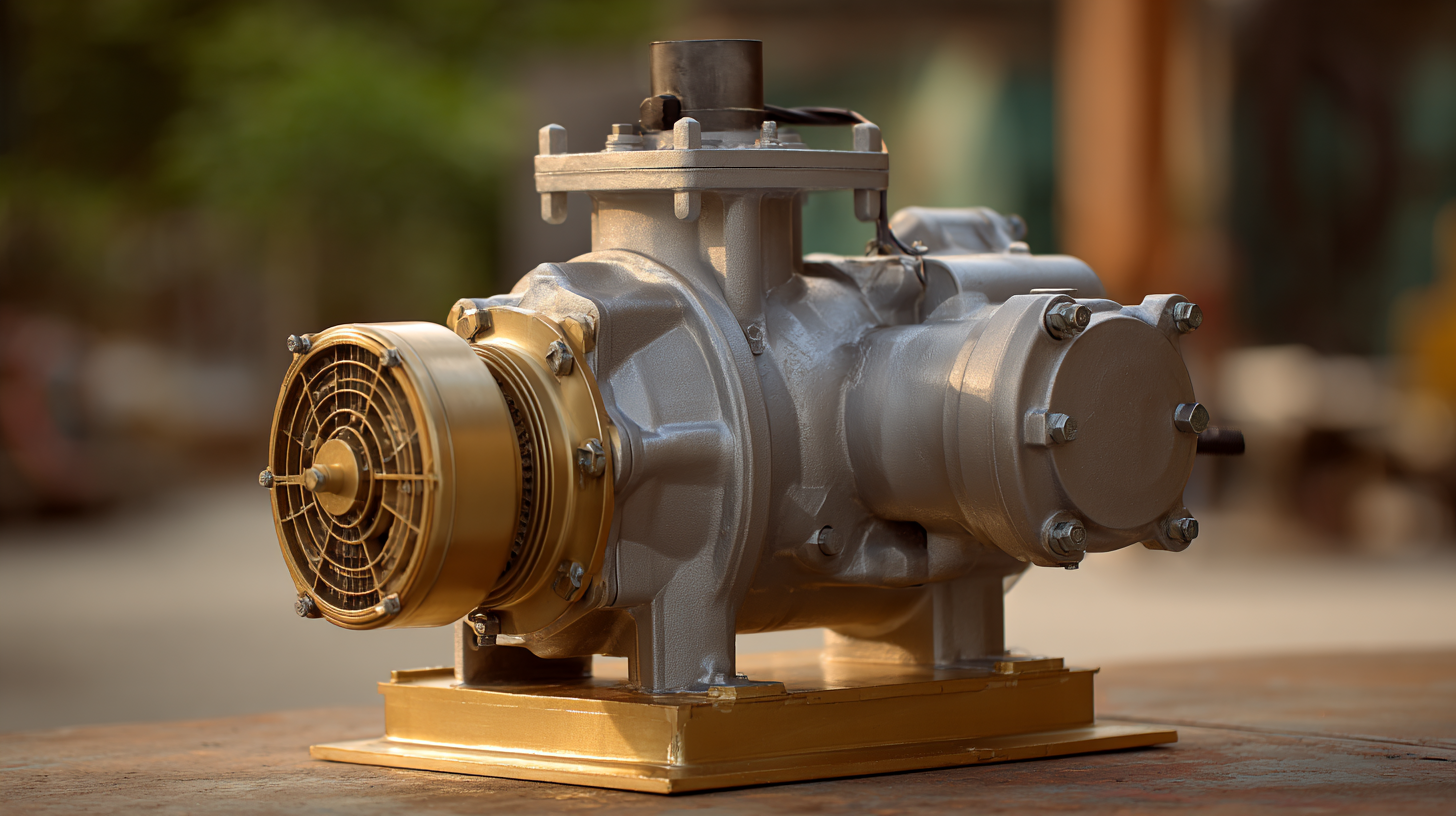

Top 10 Blower Pumps for Efficient Air Movement

This chart showcases the performance ratings of the top 10 blower pumps, illustrating their efficiency in air movement. Higher ratings indicate better performance, crucial for various applications demanding optimal output.

Related Posts

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications

-

7 Best Air Tech Innovations Transforming Your Home Experience

-

Exploring Air Vacuum Innovations at the 138th China Import and Export Fair 2025