Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications

In the realm of industrial applications, the efficiency of rotary pumps stands as a crucial factor for achieving optimal performance and cost-effectiveness. These versatile devices, known for their ability to handle various liquids, have become indispensable in sectors ranging from manufacturing to chemical processing. This comprehensive guide aims to delve into the nuances of rotary pump operation, addressing critical aspects such as design constraints, maintenance practices, and troubleshooting strategies. By exploring the intricate mechanics of rotary pumps and offering practical tips for maximizing their efficiency, this resource will empower professionals to enhance their operations. Ultimately, understanding the intricacies of rotary pumps not only leads to improved productivity but also contributes to sustainable practices in industrial environments.

Understanding the Fundamentals of Rotary Pump Design and Operation in Industry

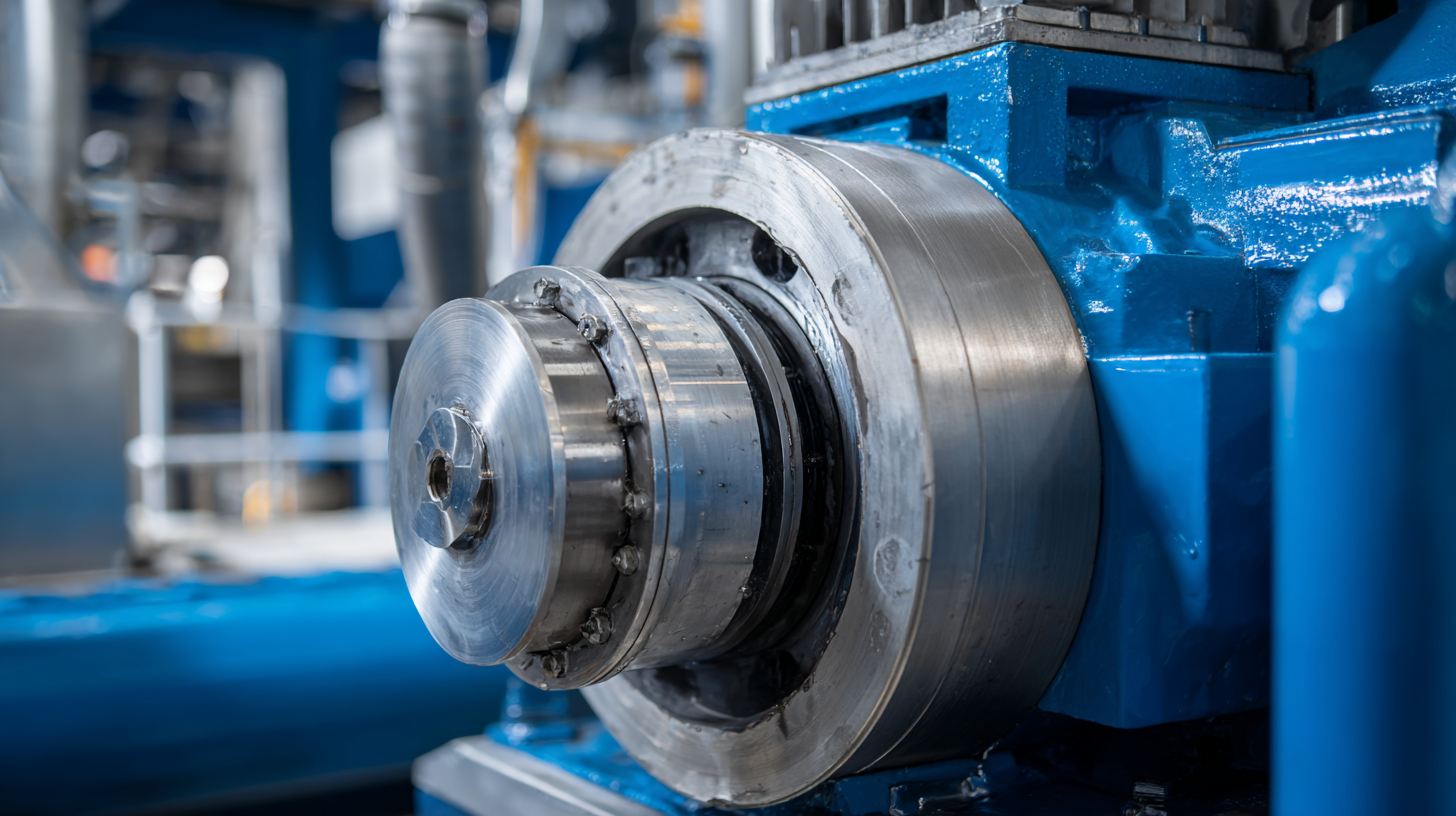

Rotary pumps are essential components in various industrial applications, characterized by their ability to move fluids efficiently. Understanding the fundamentals of rotary pump design and operation is crucial for optimizing their performance in settings such as manufacturing, oil and gas, and wastewater treatment. The design of rotary pumps involves intricate engineering that allows for controlled flow rates and pressure configurations, making them suitable for both low and high-viscosity fluids.

The operation of these pumps relies on the rotational movement of internal components, such as gears or vanes, to create a vacuum that draws fluid into the pump chamber. Once inside, the fluid is sealed and transported through the pump system, demonstrating the importance of precision in both the design and maintenance of the pump. Factors such as material selection, clearances, and proper lubrication play a significant role in enhancing the operational efficiency and lifespan of rotary pumps, ensuring they meet the rigorous demands of industrial environments.

Efficiency Comparison of Rotary Pumps in Industrial Applications

This chart illustrates the efficiency of different types of rotary pumps used in various industrial applications. The data represents the average efficiency percentages based on operational performance.

Key Performance Metrics: Flow Rate, Efficiency, and NPSH in Rotary Pumps

When evaluating the performance of rotary pumps in industrial applications, three key metrics stand out: flow rate, efficiency, and Net Positive Suction Head (NPSH). The flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), indicates the volume of fluid that a pump can deliver under specific conditions. Achieving optimal flow rates is crucial for system performance, as insufficient flow can lead to process inefficiencies and equipment failure.

Efficiency is another vital aspect, reflecting how well the pump converts mechanical energy into hydraulic energy. High-efficiency rotary pumps minimize energy consumption while maximizing output, which is essential for maintaining operational costs and reducing environmental impact. Thus, selecting a pump with the right balance of flow rate and efficiency can lead to substantial savings and improved system reliability.

Lastly, NPSH is a critical factor that ensures the pump operates without cavitation, which can cause significant damage. NPSH represents the amount of pressure available at the pump inlet above the vapor pressure of the liquid being pumped. Understanding NPSH requirements and available NPSH in a system helps prevent cavitation, ensuring the longevity and performance of rotary pumps in demanding industrial environments.

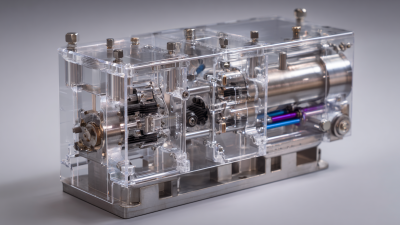

Comparative Analysis of Rotary Pump Types: Gear, Vane, and Lobe Pumps

Rotary pumps are essential in various industrial applications, and understanding the differences among the three main types—gear, vane, and lobe pumps—can significantly impact efficiency and operational costs. According to a 2022 report by the Hydraulic Institute, gear pumps are often favored for their high efficiency and compact design, making them ideal for transferring viscous fluids. These pumps can achieve efficiencies exceeding 90%, particularly in applications like lubrication systems and hydraulic fluids. However, they are more sensitive to changes in viscosity and pressure fluctuations.

Vane pumps, on the other hand, provide a unique advantage in operations requiring variable flow rates. The same Hydraulic Institute report indicates that vane pumps can maintain a consistent flow despite varying inlet conditions, achieving around 85% efficiency in such scenarios. This adaptability makes them particularly suitable for applications in chemical processing and fuel dispensing. Meanwhile, lobe pumps excel in handling shear-sensitive fluids, with capabilities to process slurries or fragile materials. They typically operate at lower efficiencies—around 70%—but their ability to handle these unique applications makes them indispensable in food processing and pharmaceutical industries. Understanding these characteristics is crucial for selecting the right pump type tailored to specific industrial needs.

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications

| Pump Type | Efficiency (%) | Flow Rate (L/min) | Pressure Range (bar) | Applications |

|---|---|---|---|---|

| Gear Pump | 85 | 100 | 5-15 | Hydraulic Systems, Fuel Oil Transfer |

| Vane Pump | 90 | 80 | 3-12 | Chemical Processing, Water Treatment |

| Lobe Pump | 95 | 60 | 2-10 | Food Processing, Pharmaceutical |

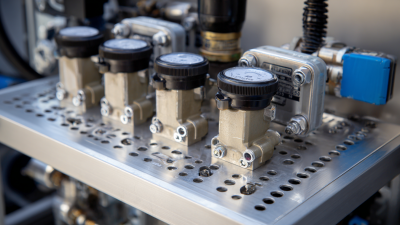

Optimizing Maintenance Strategies to Enhance Rotary Pump Efficiency

Optimizing maintenance strategies for rotary pumps is crucial for enhancing their efficiency, especially in industrial applications where performance stability is paramount. Recent developments in pump technology highlight the importance of innovative design approaches, such as utilizing new tubing designs in rotary peristaltic pumps. By predicting and mitigating flow pulsation through advanced simulations, engineers can significantly improve operational consistency and reduce wear on pump components. For instance, research indicates that optimizing roller diameters can lead to a 20% decrease in pressure fluctuations and mass flow drops, showcasing a direct correlation between design adjustments and efficiency improvement.

Moreover, as the global positive displacement pump market is projected to grow at a compound annual growth rate of 6.91% from 2019 to 2032, the relevance of efficient maintenance strategies becomes ever more critical. Companies are increasingly recognizing that investing in enhanced maintenance protocols not only prolongs pump life but also contributes to operational cost savings. By integrating predictive maintenance techniques and employing real-time monitoring, industrial operations can ensure that rotary pumps function at their optimal efficiency, leading to increased productivity and reduced downtime.

Real-World Case Studies: Efficiency Improvements in Industrial Applications using Rotary Pumps

The efficiency of rotary pumps has become a focal point for industries looking to optimize operations and reduce energy costs. In a study conducted by the Hydraulic Institute, it was reported that improving pump efficiency by just 10% can lead to a significant decrease in operating costs, potentially saving businesses over $30,000 annually, depending on system size and application. Real-world case studies demonstrate the impact of these efficiency enhancements. For instance, a chemical processing plant implemented a high-efficiency rotary pump, resulting in a 15% increase in flow rate while simultaneously decreasing power consumption by 20%. This shift not only improved productivity but also extended the lifespan of the pump, minimizing maintenance expenses.

Another example can be seen in the water treatment sector, where a municipality upgraded their rotary pumps to a more energy-efficient model. The Energy Information Administration reported that this transition led to a reduction in energy usage by approximately 18%, translating into annual savings of over $50,000. Additionally, the smoother operation of the new pumps reduced noise pollution and vibration, creating a better working environment for staff and surrounding communities. Such case studies highlight the tangible benefits of investing in high-efficiency rotary pumps for industrial applications, showcasing not only potential cost savings but also enhanced operational performance and sustainability.

Related Posts

-

Revolutionizing Industries with Tailored Custom Engineering Solutions

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

How to Choose the Right Suction Pump for Your Specific Needs

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

-

Exploring Air Vacuum Innovations at the 138th Canton Fair 2025