How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

In today's competitive industrial landscape, maximizing operational efficiency is paramount for facility managers seeking to reduce costs and enhance productivity. One of the innovative solutions gaining traction in various applications is the use of regenerative blowers. These versatile devices not only improve airflow and manage air pressure effectively but also contribute significantly to energy savings and sustainability efforts. By integrating regenerative blowers into your facility's operations, you can streamline processes, reduce noise pollution, and minimize maintenance downtime. This guide will delve into the strategies for optimizing your facility's efficiency through the intelligent application of regenerative blowers, underscoring insights and data that illustrate their impact on operational success. Discover how leveraging these advanced technologies can transform your facility, making it more efficient and responsive to the demands of modern industry.

Identifying Key Performance Metrics for Regenerative Blower Efficiency in Industrial Applications

To optimize your facility's efficiency with regenerative blowers, it’s crucial to identify and monitor key performance metrics that track their efficiency in industrial applications. The most pertinent metrics include airflow rate, energy consumption, and pressure capabilities. By systematically measuring these data points, facilities can make informed decisions on maintenance, operation adjustments, and even upgrades to enhance performance.

**Tips:** Regularly auditing the airflow rates can help identify blockages or inefficiencies in the system, enabling timely interventions. Additionally, monitoring energy consumption patterns can unveil opportunities for operational adjustments that result in cost savings and improved efficiency. Implementing advanced sensor technologies can also provide real-time data on pressure capabilities, allowing for immediate corrective actions whenever performance dips below optimal levels. These targeted strategies not only improve the regenerative blower's efficiency but also contribute to the overall operational excellence of industrial facilities.

In essence, focusing on these key performance metrics allows for pinpointing areas for improvement while ensuring that regenerative blowers operate at their best, ultimately driving down costs and enhancing productivity.

Evaluating Energy Consumption Patterns: Data-Driven Insights for Optimal Regenerative Blower Usage

Evaluating energy consumption patterns is crucial for optimizing the use of regenerative blowers in any facility. By analyzing data on energy usage, facilities can identify peak operational times and adjust blower use accordingly. This not only enhances efficiency but also contributes to significant cost savings. Keeping track of energy consumption data empowers businesses to make informed decisions about the deployment and scheduling of regenerative blowers.

Tip: Implement an energy monitoring system to continuously track the performance of your blowers. By analyzing the data over time, you can spot trends and areas for improvement.

Additionally, regular maintenance of regenerative blowers can improve energy efficiency. Clogged filters and worn-out components can lead to increased energy consumption. Scheduling routine checks and cleaning can keep the blowers operating at their best, ensuring optimal performance.

Tip: Design a maintenance schedule based on usage patterns to ensure your regenerative blowers are always operating efficiently.

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data - Evaluating Energy Consumption Patterns

| Facility Type | Average Energy Consumption (kWh) | Operational Hours per Week | Efficiency Rating (%) | Cost Savings ($/week) |

|---|---|---|---|---|

| Manufacturing | 3500 | 40 | 85 | 450 |

| Food Processing | 2700 | 50 | 90 | 360 |

| Pharmaceutical | 4200 | 60 | 92 | 500 |

| Textile | 3100 | 45 | 80 | 420 |

| Automotive | 3900 | 55 | 88 | 475 |

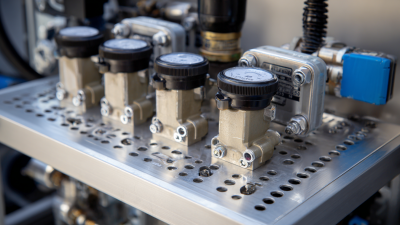

Integrating Advanced Control Systems to Enhance Regenerative Blower Operational Efficiency

Integrating advanced control systems into your regenerative blower operations can significantly enhance their efficiency and effectiveness. Modern control technologies, such as variable frequency drives (VFDs) and smart sensors, enable real-time monitoring and adjustment of blower parameters. According to a report by the Department of Energy, implementing VFDs can improve energy savings by up to 50%, as these systems allow for precise speed control according to process demands, minimizing energy wastage.

Tips for optimizing your regenerative blower efficiency include scheduling regular maintenance to ensure all components are running smoothly, and utilizing software for predictive analytics. With predictive maintenance, companies can avoid unexpected failures, thus minimizing downtime and extending the equipment's lifespan.

Furthermore, leveraging advanced data analytics can help in understanding operational patterns, leading to better decision-making. By analyzing collected data, facility managers can identify inefficiencies and optimize blower performance in alignment with production needs. Reports suggest that facilities employing data-driven management strategies can see a productivity increase of up to 20%, demonstrating the significant impact of integrating technology in operational workflows.

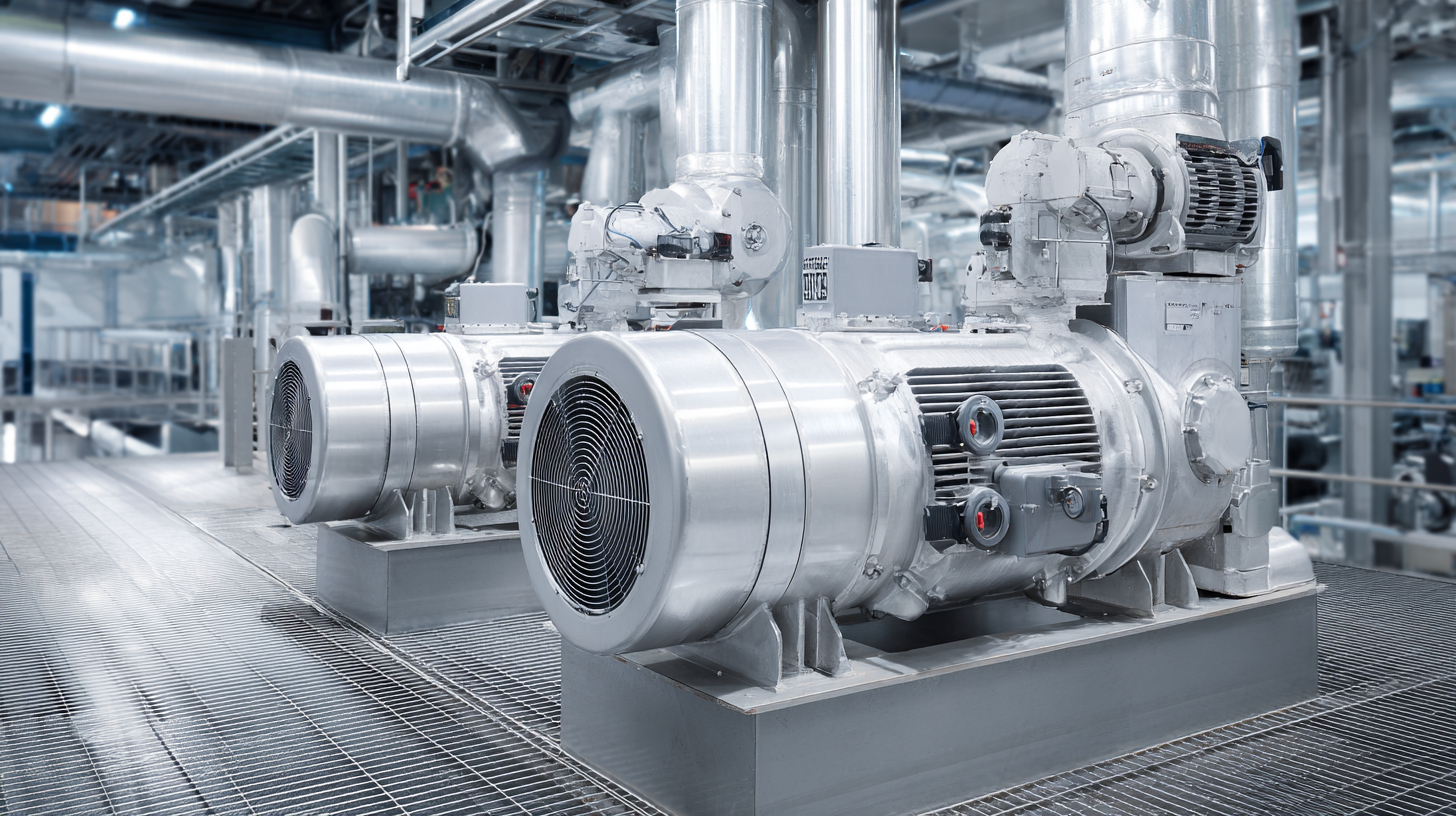

Comparative Analysis of Regenerative Blowers vs. Traditional Blowers: Performance Data and ROI

Regenerative blowers have emerged as a powerful alternative to traditional blowers, particularly in applications requiring consistent airflow and energy efficiency. According to a report by the Fluid Power Journal, regenerative blowers can achieve energy savings of up to 30% compared to their traditional counterparts. This reduction is primarily due to their ability to constructively harness ambient air, thereby minimizing energy loss during operation. In facility applications such as waste water treatment and material handling, these savings translate into significant decreases in operational costs, making them an attractive option for businesses looking to optimize efficiency.

Furthermore, performance data indicates that regenerative blowers provide superior pressure stability and lower noise levels. The American Society of Mechanical Engineers (ASME) notes that regenerative blowers can maintain a steady pressure of around 10 to 30 inches of water column with minimal fluctuation, unlike traditional blowers, which often show performance variability under load. This consistency not only enhances process reliability but also contributes to a more comfortable working environment. Additionally, the return on investment (ROI) for switching to regenerative blowers is compelling, with many facilities experiencing payback periods of less than two years due to reduced energy costs and lower maintenance requirements.

Comparative Analysis of Regenerative Blowers vs. Traditional Blowers

This chart compares the energy efficiency and return on investment (ROI) of regenerative blowers against traditional blowers, showcasing the advantages of regenerative technology in a facility's operational efficiency.

Exploring Maintenance Best Practices to Maximize the Lifespan and Efficiency of Regenerative Blowers

Regenerative blowers are vital for enhancing operational efficiency in various industrial applications, from wastewater treatment to packaging lines. To maximize their lifespan and performance, implementing robust maintenance best practices is essential. According to the 2022 Blower and Vacuum Technology Report by the Industrial Air & Gas Processing Association, facilities that adhere to a regular maintenance schedule can extend the lifespan of their blowers by 30% and improve energy efficiency by up to 15%. This emphasizes the importance of proactive maintenance in reducing operational costs.

Regular inspection and cleaning of the blower's intake and discharge ports can prevent the buildup of dust and debris, which are common culprits of decreased performance. Moreover, monitoring key parameters such as pressure and temperature can help in detecting issues before they lead to significant failures. A study from the International Journal of Fluid Machinery and Systems found that facilities conducting quarterly maintenance saw a 25% reduction in unexpected downtime. By prioritizing systematic maintenance, facilities can not only enhance the efficiency of their regenerative blowers but also contribute to a more sustainable and cost-effective operation.