Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

In recent years, the industrial sector has increasingly recognized the pivotal role of liquid ring vacuum pumps in streamlining operations and enhancing efficiency. According to a report by Research and Markets, the global vacuum pump market is projected to reach USD 9.64 billion by 2026, with liquid ring vacuum pumps commanding a significant share due to their reliability and performance in challenging applications. Unlike traditional vacuum pumps, liquid ring vacuum pumps operate using liquid as a sealing medium, which not only minimizes operational noise but also offers superior performance in handling moisture-laden gases. With industries ranging from pharmaceuticals to food processing experiencing a surge in demand for efficient and sustainable solutions, understanding the advantages of liquid ring vacuum pumps is essential. This guide will explore how these innovative pumps can optimize processes and contribute to the overall success of modern industrial applications.

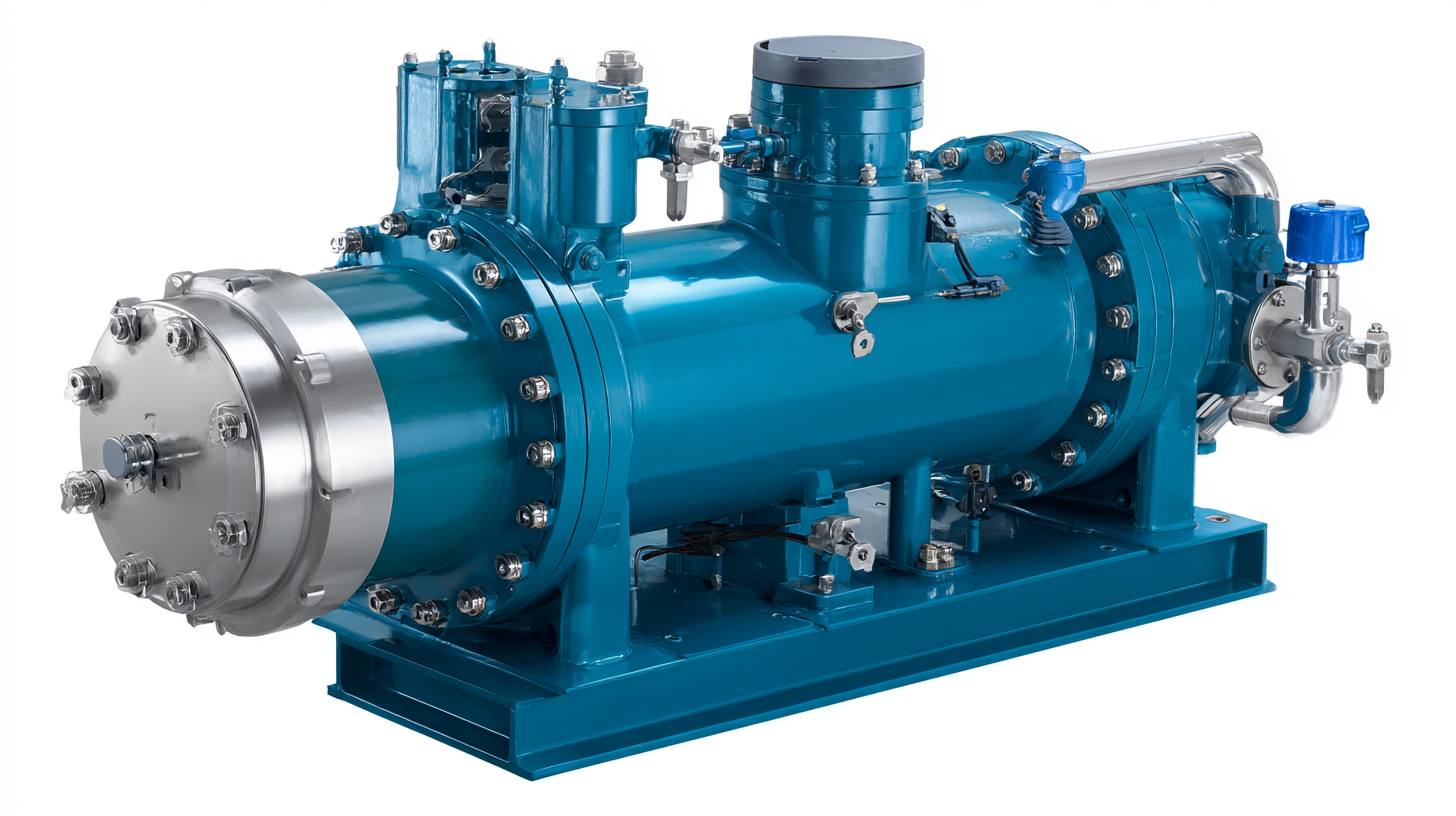

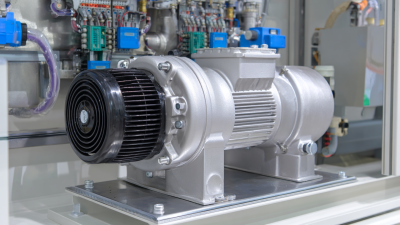

How Liquid Ring Vacuum Pumps Operate: A Technical Overview

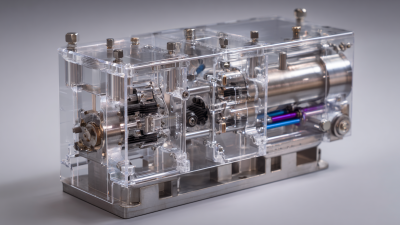

Liquid ring vacuum pumps operate on a simple yet effective principle involving a cyclic process of suction, compression, discharge, and expansion. This mechanism allows them to create a vacuum efficiently while handling vapor and gas mixtures, making them particularly suited for various industrial applications. As highlighted in recent market reports, the liquid ring vacuum pump market was valued at approximately USD 692.5 million in 2023, with projected growth stemming from their ability to meet rising operational demands across sectors. Notably, these pumps excel in environments where wet vapors are present, as they operate with a liquid seal, enhancing both reliability and performance.

Tips: When selecting a liquid ring vacuum pump, consider the type—whether single-stage or two-stage—as this can significantly impact efficiency and suitability for specific applications. Additionally, the choice of materials, such as stainless steel, can affect durability and resistance to corrosive environments.

Recent developments in the industry have led to innovations in liquid ring vacuum pump design, enhancing their efficiency and performance. A theoretical model based on the actual operating cycle has been proposed to better predict pump performance, further solidifying their role in modern processing plants. This continuous advancement is crucial, as industries are increasingly focused on optimizing operations and minimizing energy consumption, with a market growth rate projected at a CAGR of 3.9% from 2024 to 2032.

Key Benefits of Liquid Ring Vacuum Pumps in Industrial Settings

Liquid ring vacuum pumps are gaining traction in various industrial applications due to their numerous advantages. One significant benefit is their operational efficiency, which allows for continuous, reliable performance without the need for extensive maintenance. This characteristic is particularly appealing in industries that operate around the clock, where downtime can lead to considerable losses. Furthermore, liquid ring vacuum pumps are known for their ability to handle wet and humid gases, making them ideal for processes involving condensation, such as food and beverage packaging, including sustainable beer bottling.

Additionally, the growing market for liquid ring vacuum pumps reflects the increasing demand for efficient industrial solutions. As the market is projected to grow at a CAGR of 3.9% between 2024 and 2032, businesses are prioritizing technologies that offer cost-effective and environmentally friendly options. The robustness and reliability of liquid ring vacuum pumps in various settings underline their significance in modern industrial processes, contributing not only to operational efficiency but also to sustainability efforts in manufacturing and production sectors.

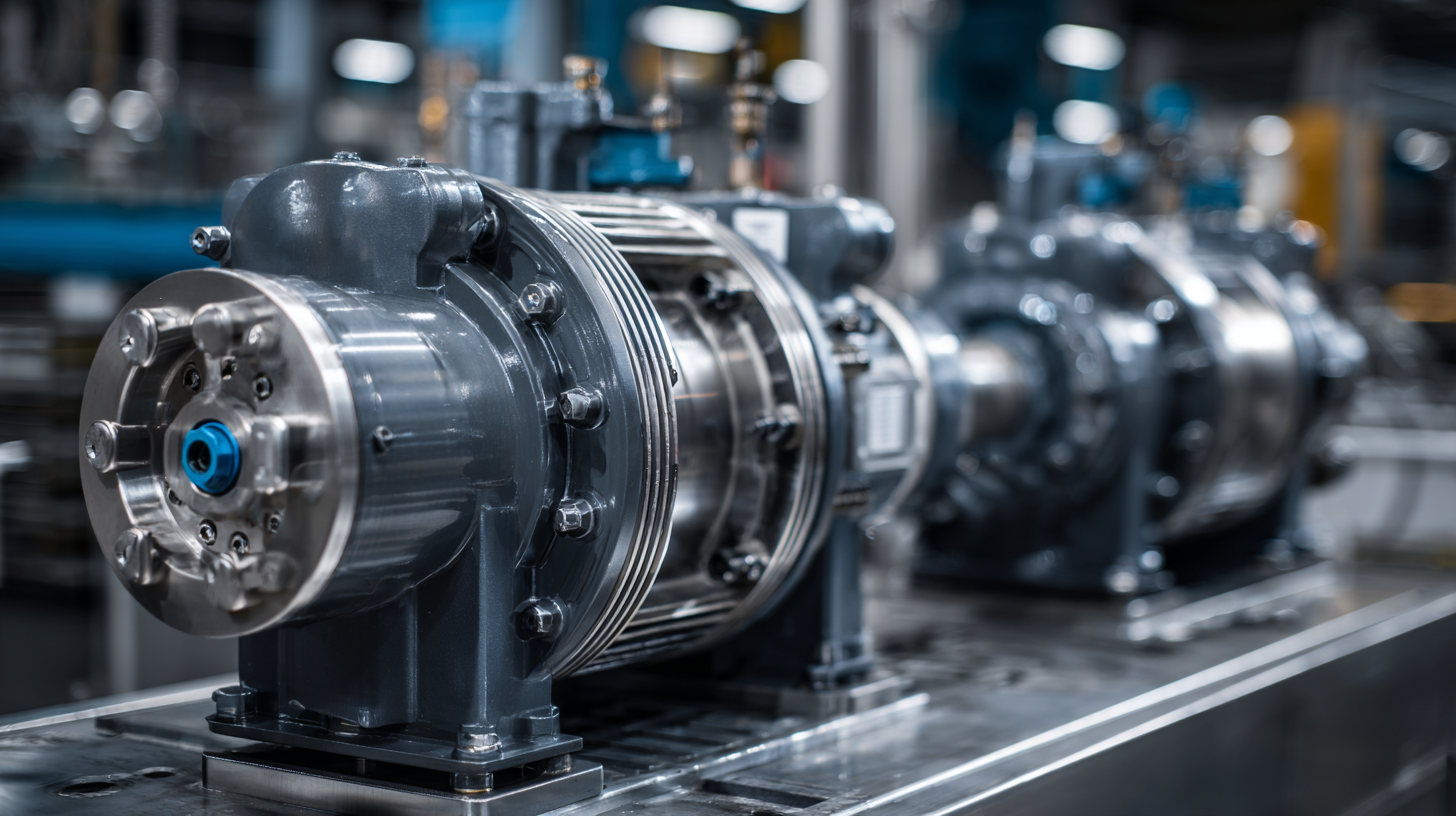

Comparing Liquid Ring Vacuum Pumps with Alternative Vacuum Solutions

Liquid ring vacuum pumps have emerged as a preferred choice in various industrial applications due to their unique operational advantages. A key comparison lies between liquid ring vacuum pumps and other vacuum solutions such as rotary vane and screw vacuum pumps. According to a recent report by the Vacuum Technology Association, liquid ring pumps exhibit a significantly lower operating cost, with energy savings of up to 30% compared to traditional rotary vane pumps. This is primarily attributed to the liquid ring’s ability to maintain efficiency across varying pressures, making it ideal for applications requiring consistent performance over prolonged periods.

Moreover, liquid ring vacuum pumps are known for their robustness in handling moist or vaporous gases, which often pose challenges for alternative technologies. For instance, while rotary vane pumps may suffer from increased wear and reduced efficiency in wet conditions, liquid ring pumps remain effective, as highlighted in a 2022 technical review by the International Journal of Vacuum Science. This adaptability not only extends the life of the equipment but also decreases maintenance costs significantly, positioning liquid ring technology as a sustainable option in sectors ranging from chemical processing to food packaging. Furthermore, their simple design enables easier maintenance, reducing downtime and improving overall productivity.

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

| Feature | Liquid Ring Vacuum Pumps | Alternative Vacuum Solutions |

|---|---|---|

| Operating Principle | Uses liquid to create a vacuum | Mechanical or electrical methods |

| Efficiency | High efficiency at low pressures | Varies greatly based on method |

| Maintenance | Lower maintenance requirements | Higher maintenance requirements |

| Noise Level | Generally quieter operation | Can be noisy depending on design |

| Cooling Requirement | Requires cooling for the liquid | Heat dissipation varies by type |

| Applications | Used in food processing, pharmaceuticals | Used in manufacturing, packaging |

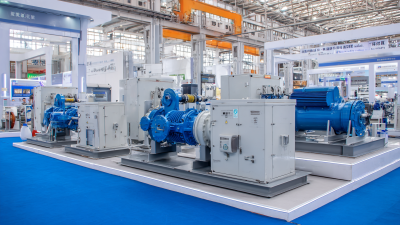

Applications of Liquid Ring Vacuum Pumps in Various Industries

Liquid ring vacuum pumps have become indispensable in various industrial sectors due to their unique operational advantages. These pumps find applications in chemical processing, pharmaceuticals, food production, and even wastewater treatment. Their ability to handle a wide range of gases, including those containing moisture and particulates, makes them highly versatile. For instance, in the pharmaceutical industry, liquid ring vacuum pumps ensure a sterile environment during the production of medications by efficiently removing air and other contaminants without compromising product quality.

One of the standout advantages of liquid ring vacuum pumps is their relatively low maintenance requirement compared to other vacuum technologies. This makes them an attractive option for industries where uptime is critical. Tips for maximizing the performance of these pumps include regular monitoring of the operating fluid levels and ensuring proper alignment during installation. Additionally, industries should consider using variable frequency drives (VFDs) to control the pump speed, providing greater energy efficiency and adaptability to changing operational demands.

In the food production sector, liquid ring vacuum pumps are commonly employed for packaging processes that require low-pressure environments to prolong shelf life. They excel in not only maintaining vacuum conditions but also in enhancing the quality of the final product. To ensure optimal performance, it’s advisable to inspect seals and fluid condition periodically, as these factors directly impact efficiency and pump longevity.

Maintenance Tips for Ensuring Optimal Performance of Liquid Ring Vacuum Pumps

To ensure optimal performance of liquid ring vacuum pumps, regular maintenance is crucial. One of the key tips is to routinely check the liquid levels in the pump. Maintaining the proper liquid level not only ensures efficient operation but also helps in cooling and lubrication, which can significantly extend the life of the pump components. Additionally, users should monitor the quality of the pump liquid; contaminated or degraded liquids can lead to inefficiencies and potential damage.

Another important aspect of maintenance involves inspecting seals and gaskets for wear and tear. Damaged seals can lead to leaks, which compromises both the vacuum quality and the pump's operational efficiency. Regularly replacing these components as part of a preventative maintenance schedule can save costs and reduce unforeseen downtime. Lastly, cleaning the pump regularly from any debris or buildup will help maintain airflow and performance. By following these maintenance tips, industries can ensure their liquid ring vacuum pumps operate at peak efficiency, thereby enhancing overall productivity.

Related Posts

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

How to Choose the Right Vacuum Industrial Solutions for Your Business Needs

-

Exploring Air Vacuum Innovations at the 138th China Import and Export Fair 2025

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data