Unveiling the Secrets: How High Vacuum Pumps Revolutionize Scientific Research and Industry

In the realm of scientific research and industrial applications, the advent of high vacuum pumps has catalyzed a revolution, transforming methodologies and enhancing precision across various fields. These crucial devices create an environment devoid of air or gases, allowing scientists and engineers to conduct experiments and processes that were once thought impossible under atmospheric pressure. As we delve into the secrets of high vacuum pumps, it becomes evident that their role extends beyond mere functionality; they are pivotal in advancing innovation and expanding our understanding of fundamental principles in physics, chemistry, and materials science.

The impact of high vacuum pumps is felt across a spectrum of industries, from semiconductor manufacturing to nanotechnology development. By providing an ultra-clean and controlled environment, they enable researchers to manipulate materials at the atomic level, thus fostering breakthroughs that drive progress and economic growth. This exploration will highlight the top five ways high vacuum pumps have revolutionized scientific research and industry, showcasing their undeniable importance in today's technological landscape. As we unveil these secrets, we will also reflect on the future advancements that high vacuum pump technology holds, poised to further enhance the boundaries of human knowledge and capability.

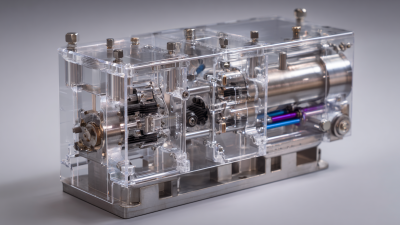

Understanding High Vacuum Pumps: Principles and Functions Explained

High vacuum pumps are essential tools in various scientific and industrial applications, providing an environment free of atmospheric contamination. These pumps operate on the principle of creating a vacuum by removing gas molecules from a sealed chamber, which can lower the pressure to levels below 10^-6 torr. This capability is crucial for processes like molecular beam epitaxy in semiconductor manufacturing and advanced research in particle physics. According to a report by MarketsandMarkets, the global high vacuum pumps market is projected to grow from $1.5 billion in 2020 to $2.1 billion by 2025, highlighting their increasing role in modern technology.

When using high vacuum pumps, it’s important to consider their maintenance and efficiency. Regularly checking the oil levels and replacing filters can prevent contamination and ensure optimal performance. Additionally, employing a combination of rotary and turbomolecular pumps can enhance the vacuum level and speed up the pumping process. For labs and industries heavily reliant on vacuum technology, understanding the differential pressure and pumping speed ratings is critical to select the right equipment.

Tip: Always calibrate your vacuum system to maintain accurate pressure readings. This helps in ensuring reproducibility of experiments, especially in sensitive processes like thin film deposition or electron microscopy. Additionally, investing in high-quality, reliable pumps will save costs in the long term by reducing maintenance frequency and downtime.

Unveiling the Secrets: How High Vacuum Pumps Revolutionize Scientific Research and Industry

| Application Area | Pump Type | Operating Pressure Range (mbar) | Typical Use | Efficiency |

|---|---|---|---|---|

| Semiconductor Manufacturing | Turbo Molecular Pump | 10-3 to 10-7 | Vacuum deposition processes | High (>90%) |

| Research Laboratories | Rotary Vane Pump | 1 to 10-3 | General vacuum applications | Moderate (70-80%) |

| Coating Technologies | Diffusion Pump | 10-2 to 10-8 | Thin film deposition | High (>90%) |

| Medical Equipment | Scroll Pump | 1 to 10-3 | Vacuum packaging and sterilization | High (80-85%) |

| Analytical Chemistry | Hybrid Pumps | 1 to 10-5 | Mass spectrometry and gas analysis | Very High (>95%) |

The Role of High Vacuum Pumps in Scientific Research Advancements

High vacuum pumps have become indispensable tools in various fields of scientific research, driving innovations that lead to groundbreaking discoveries. By achieving pressures as low as 10-9 torr, these pumps enable researchers to conduct experiments in ultra-clean environments, which are crucial for studying sensitive materials and phenomena. According to the American Vacuum Society, advancements in high vacuum technology have significantly improved the performance of experiments in areas such as particle physics, semiconductor manufacturing, and surface science.

Tips: When selecting a high vacuum pump for your research, consider the specific pressure range and volume requirements based on your application's needs. Different pump technologies, such as turbomolecular or diffusion pumps, offer distinct advantages depending on the material properties you intend to work with.

Furthermore, high vacuum systems facilitate the synthesis of novel materials by minimizing contamination risks during reactions. A report by the International Association for the Properties of Water and Steam highlights that high vacuum environments can enhance the production of thin films and nanostructured materials, vital in the development of next-generation electronic devices. By removing gases and impurities, high vacuum pumps play a crucial role in optimizing chemical reactions and material properties, ultimately pushing the boundaries of scientific exploration.

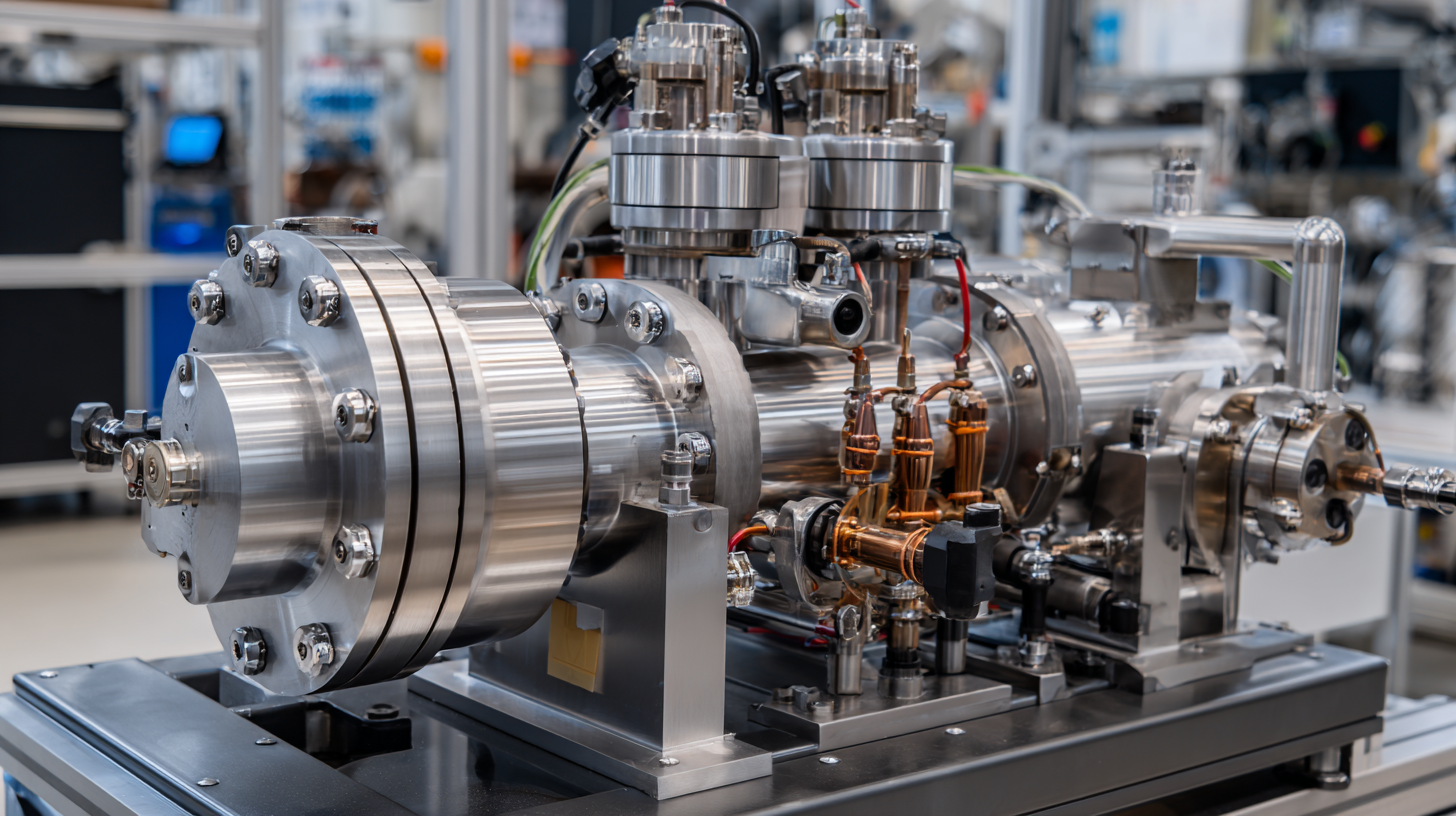

Industrial Applications of High Vacuum Pumps: From Manufacturing to Space Exploration

High vacuum pumps play a pivotal role in various industrial applications, significantly enhancing processes across multiple sectors. In manufacturing, these pumps are essential for semiconductor fabrication, where maintaining a controlled environment is crucial for producing high-quality microchips. By removing impurities and moisture, high vacuum pumps enable the deposition of thin films and etching processes, ensuring precision and reliability in electronic components. Their ability to create and maintain ultra-low pressures allows for optimal conditions in chemical vapor deposition (CVD) and other critical manufacturing tasks.

In addition to manufacturing, high vacuum pumps are vital in the field of space exploration. They facilitate the creation of vacuum chambers that simulate the conditions of outer space, which is essential for testing spacecraft and satellite components before launch. This rigorous testing ensures that equipment can withstand the harsh environments of space, including extreme temperatures and radiation. Moreover, high vacuum technology is crucial for the development of propulsion systems and other advanced technologies that enable missions beyond Earth. With ongoing innovations in high vacuum technology, the possibilities for industrial applications continue to expand, driving advancements in science and engineering.

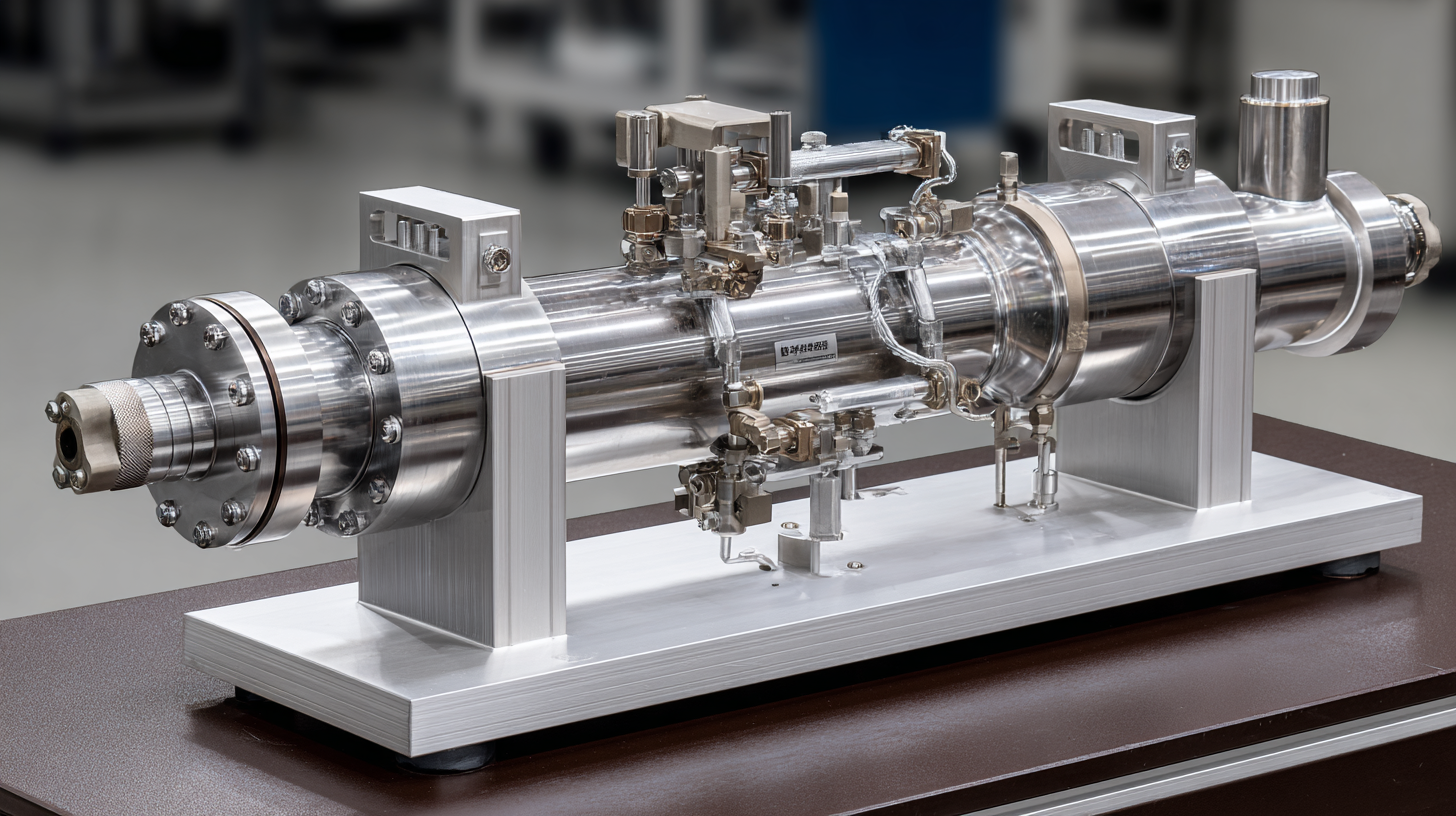

Innovations in High Vacuum Pump Technology: Enhancements and Future Trends

Recent advancements in high vacuum pump technology have significantly transformed both scientific research and various industrial applications. Innovations such as molecular pumps and turbo molecular pumps have dramatically improved the efficiency and reliability of vacuum systems. These pumps are increasingly capable of reaching ultra-high vacuum levels, which are essential for experiments in material science, semiconductors, and particle physics. The introduction of advanced materials like carbon nanotubes and specialized coatings also contributes to the enhanced performance and longevity of these pumps, making them indispensable tools in cutting-edge research.

Looking to the future, we can expect further developments that will push the boundaries of high vacuum technology. The integration of digital monitoring and control systems will allow for real-time adjustments and optimizations, enhancing operational efficiency. Additionally, as industries focus more on sustainability, future innovations may emphasize energy-efficient designs and eco-friendly materials, thereby reducing the environmental impact of vacuum systems. The synergy between high vacuum pumps and emerging technologies, such as nanotechnology and quantum computing, suggests a promising horizon for both research and industrial sectors.

Unveiling the Secrets: High Vacuum Pump Technology Innovations

Challenges and Solutions in Maintaining Efficient High Vacuum Systems

High vacuum systems play a pivotal role in various scientific and industrial applications, from semiconductor manufacturing to space research. However, maintaining the efficiency of these systems presents numerous challenges. One major issue is the prevention of leakage. Even microscopic leaks can compromise the vacuum level, leading to contamination and impaired results. Regular inspection and the use of high-quality sealing materials are essential strategies to mitigate this risk. Implementing advanced leak detection technology can also help identify vulnerabilities in the system before they become critical failures.

High vacuum systems play a pivotal role in various scientific and industrial applications, from semiconductor manufacturing to space research. However, maintaining the efficiency of these systems presents numerous challenges. One major issue is the prevention of leakage. Even microscopic leaks can compromise the vacuum level, leading to contamination and impaired results. Regular inspection and the use of high-quality sealing materials are essential strategies to mitigate this risk. Implementing advanced leak detection technology can also help identify vulnerabilities in the system before they become critical failures.

Another challenge lies in the handling of outgassing materials. Many components within high vacuum systems can release gases when under vacuum, impacting both the vacuum level and the integrity of experiments. To address this, pre-treating materials and selecting low-outgassing alternatives are crucial. Additionally, maintaining optimal pump performance through routine maintenance and monitoring can enhance the overall functionality of high vacuum systems. By strategically tackling these challenges, researchers and industries can ensure the reliability and efficiency of their high vacuum processes, paving the way for groundbreaking advancements.

Related Posts

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Exploring Air Vacuum Innovations at the 138th Canton Fair 2025

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals