The Hidden Benefits of Rotary Pumps: Why They Are Essential for Modern Industries

In modern industries, the role of rotary pumps has become increasingly indispensable, offering a multitude of hidden benefits that enhance efficiency and reliability. According to a recent market analysis by Grand View Research, the global rotary pump market is projected to reach USD 4.78 billion by 2025, driven by the growing demand from sectors such as oil and gas, chemicals, and food processing. The ability of rotary pumps to handle a wide range of viscosities and flow rates while maintaining a consistent output makes them essential for various applications. Furthermore, industry reports highlight their robustness in challenging environments, which significantly reduces maintenance costs and downtime. As companies strive to optimize their operations amidst rising competition, understanding how to effectively implement rotary pumps can lead to substantial operational improvements and long-term savings, underscoring their critical role in the contemporary industrial landscape.

The Role of Rotary Pumps in Increasing Operational Efficiency Across Industries

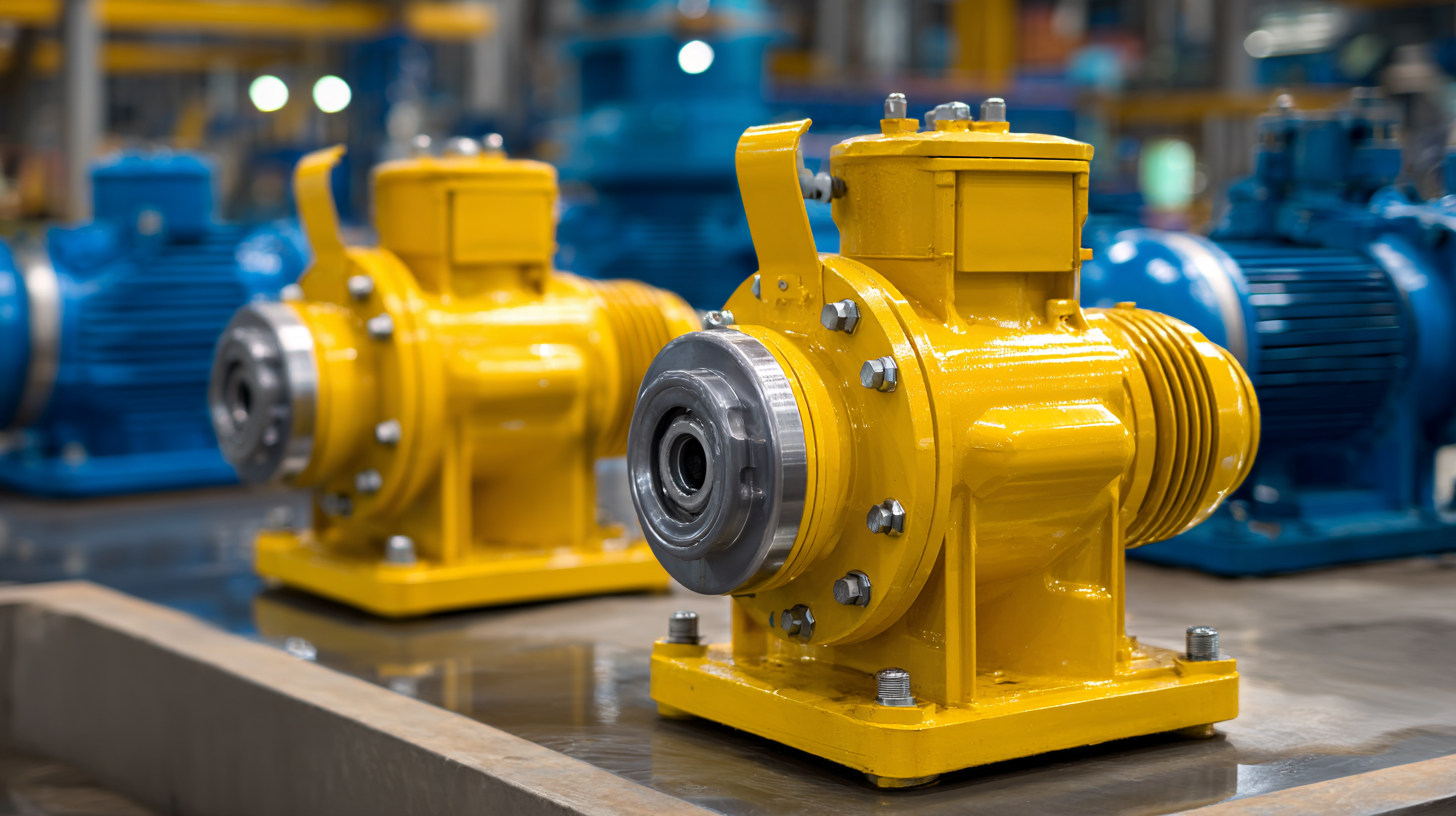

Rotary pumps play a vital role in enhancing operational efficiency across various modern industries. Their design allows for the continuous movement of fluids, making them especially valuable in applications requiring reliable and consistent flow rates. Unlike other pump types, rotary pumps maintain a steady delivery pressure, ensuring that processes run smoothly without fluctuations that could lead to bottlenecks or disruptions in production. This predictability is essential in sectors such as pharmaceuticals, food processing, and petrochemicals, where precise fluid handling is imperative.

In addition to their efficiency in fluid transfer, rotary pumps offer versatility across different applications. They can handle a wide range of liquids, from viscous fluids to low-viscosity substances, making them suitable for diverse industrial needs. This adaptability not only reduces the need for multiple types of pumps within a facility but also streamlines maintenance and operational protocols. By integrating rotary pumps into their systems, industries can optimize their workflows, decrease downtime, and ultimately enhance productivity, proving that these pumps are not just functional tools, but essential assets in modern operational strategies.

The Hidden Benefits of Rotary Pumps

| Industry | Operational Efficiency Gain (%) | Common Applications | Key Benefits |

|---|---|---|---|

| Food & Beverage | 15 | Liquid transferring, bottling | Consistent flow, hygiene |

| Pharmaceutical | 20 | API transfer, mixing | Precision, contamination control |

| Chemical Processing | 25 | Solvent transfer, batching | Durability, chemical resistance |

| Water Treatment | 10 | Chemical dosing, sludge handling | Reliability, efficiency |

| Agriculture | 18 | Irrigation, fertilizer mixing | Versatility, ease of use |

| Oil & Gas | 22 | Fuel transfer, lubrication | Robustness, high flow rate |

Key Advantages of Rotary Pumps in Fluid Transfer and Processing

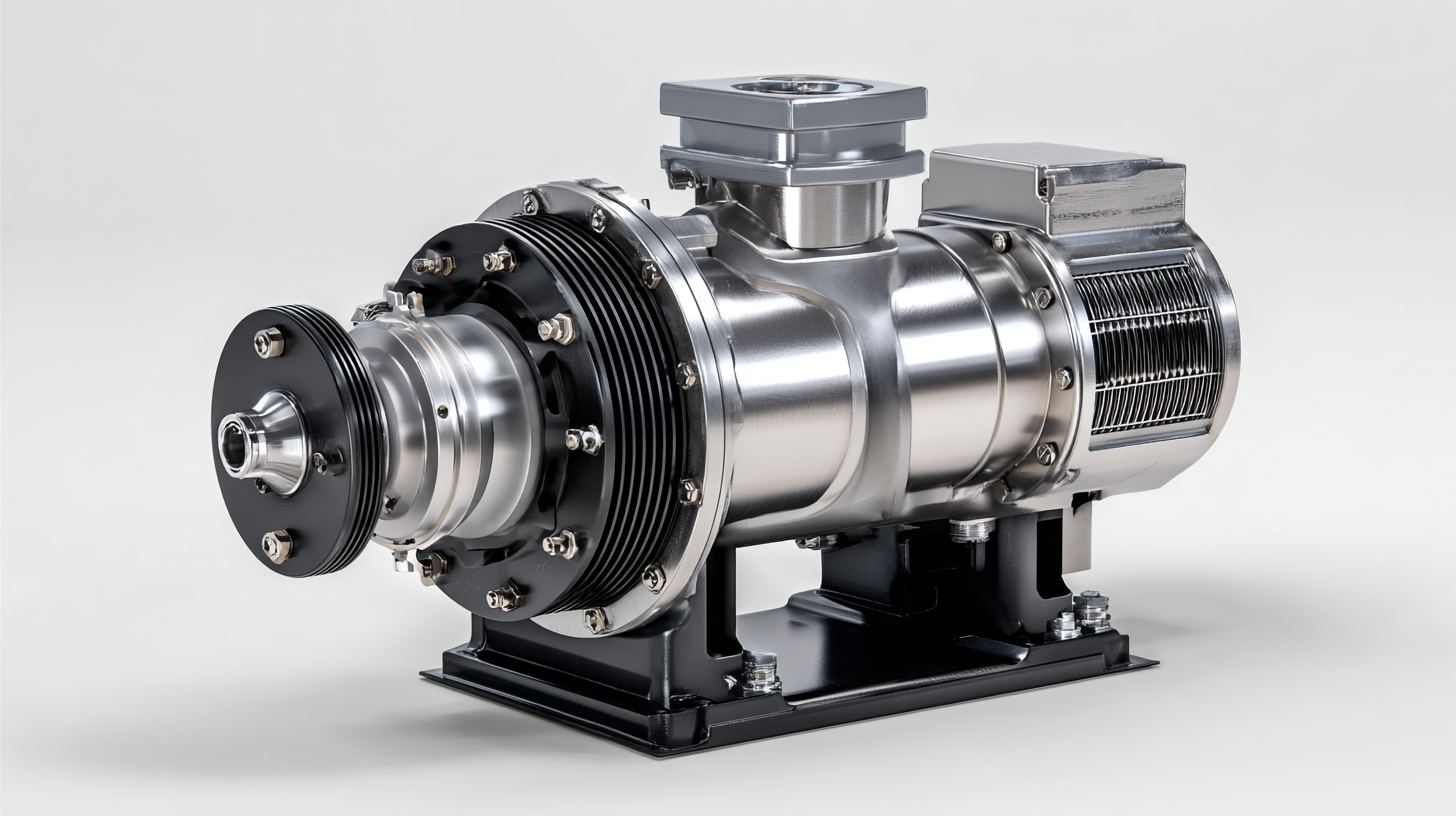

Rotary pumps have become indispensable in modern industries due to their efficiency and versatility in fluid transfer and processing. According to a recent report by MarketsandMarkets, the global rotary pump market is expected to reach USD 4.5 billion by 2025, growing at a CAGR of 5.6%. This growth is largely driven by their capability to handle a wide variety of fluids, from thick sludges to volatile chemicals, making them suitable for sectors such as oil and gas, chemicals, and food processing.

One key advantage of rotary pumps is their ability to maintain a consistent flow rate, which is crucial for processes requiring precise measurements. According to the Hydraulic Institute, the design of rotary pumps allows them to achieve higher efficiency compared to centrifugal pumps, often exceeding 80%. This efficiency not only reduces energy consumption but also minimizes operational costs, making them an attractive choice for budget-conscious industries.

Tip: When selecting a rotary pump, consider the specific viscosity of the fluids you will be working with. Different types of rotary pumps, such as gear, diaphragm, and screw pumps, excel with varying fluid densities and compositions.

Tip: Regular maintenance is essential for optimal performance. Conduct routine inspections to check for wear and tear, and replace seals and gaskets as necessary to prevent leaks and ensure efficiency.

How Rotary Pumps Contribute to Sustainable Practices in Modern Manufacturing

Rotary pumps play a pivotal role in promoting sustainable practices within modern manufacturing. Their design allows for efficient fluid movement, minimizing energy consumption compared to other pumping systems. By utilizing rotary pumps, industries can reduce their carbon footprint, as these pumps require less power to operate, thereby contributing to lower greenhouse gas emissions. This energy efficiency is essential for manufacturers aiming to meet stringent environmental regulations while simultaneously reducing operational costs.

Furthermore, rotary pumps are integral in the recycling and reuse of materials in manufacturing processes. They can handle a variety of fluids, including viscous and abrasive liquids, making them ideal for transferring recycled substances within production lines. This capability not only conserves natural resources but also aligns with circular economy principles, encouraging manufacturers to adopt sustainable methods that minimize waste. As industries increasingly focus on sustainability, the role of rotary pumps in optimizing processes and promoting eco-friendly practices becomes even more significant.

Tips for Maximizing the Performance and Longevity of Rotary Pumps

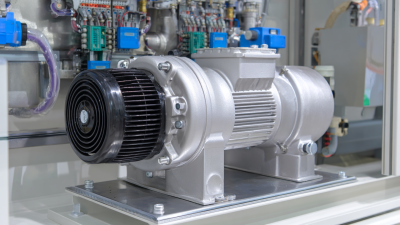

To maximize the performance and longevity of rotary pumps, regular maintenance is key. Start by ensuring the pump is correctly aligned and securely mounted to prevent excessive vibration, which can lead to premature wear. Periodic inspection of seals and bearings is critical, as any signs of wear can quickly escalate into larger issues. Utilizing the appropriate lubricants and keeping the operating environment clean can also significantly extend the lifespan of these pumps.

Another important aspect is monitoring the operating conditions to avoid running the pump outside its specified parameters. This includes keeping an eye on temperature, pressure, and flow rates. Implementing a routine check on the pump’s performance metrics will help in identifying potential problems before they arise. Lastly, investing in quality replacement parts and adhering to the manufacturer’s guidelines for operation and maintenance can greatly ensure that the rotary pump operates at its best for years to come.

Common Misconceptions About Rotary Pumps and the Truth Behind Their Use

Rotary pumps are often misunderstood, leading to pervasive misconceptions within various industries. One common myth is that rotary pumps are limited to only a narrow range of fluids. In reality, according to a report by the Pump Industry Analysts, rotary pumps are capable of handling a diverse array of liquids, including corrosive, viscous, and high-temperature fluids. This versatility makes them invaluable in sectors such as chemical processing, food and beverage, and oil and gas, where the ability to pump different types of media is crucial for operational efficiency.

Another misconception is the belief that rotary pumps require extensive maintenance and are expensive to operate. However, a study by the American Society of Mechanical Engineers found that modern rotary pumps, when properly selected and maintained, can achieve over 90% efficiency and often require less maintenance compared to centrifugal pumps. This efficiency not only reduces operational costs but also contributes to lower energy consumption, aligning with contemporary sustainability goals in industries striving to minimize their carbon footprint.

As these myths are dispelled, it becomes clear that rotary pumps play an essential role in the efficiency and reliability of many modern industrial processes.

Related Posts

-

How to Choose the Right Vacuum Industrial Solutions for Your Business Needs

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals

-

Unlocking Efficiency: The Science Behind Dry Rotary Vane Vacuum Pumps and Their Industry Applications

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

Exploring Air Vacuum Innovations at the 138th China Import and Export Fair 2025