Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

As the global demand for sustainable technologies continues to rise, the role of airtech vacuum pumps has become increasingly vital in various industrial applications. According to a recent report from MarketsandMarkets, the vacuum pump market is projected to grow to $5.9 billion by 2026, driven by advancements in environmental regulations and the push for energy efficiency across sectors.

Airtech vacuum pumps, known for their reliability and energy-saving capabilities, are at the forefront of this transformation, enabling smoother processes in industries ranging from semiconductor manufacturing to food packaging. Their unique design facilitates reduced energy consumption and minimized carbon footprints, aligning with the broader goals of sustainable development.

Airtech vacuum pumps, known for their reliability and energy-saving capabilities, are at the forefront of this transformation, enabling smoother processes in industries ranging from semiconductor manufacturing to food packaging. Their unique design facilitates reduced energy consumption and minimized carbon footprints, aligning with the broader goals of sustainable development.

This article explores the future trajectory of airtech vacuum pumps within the sustainable technologies landscape, emphasizing their critical contributions to innovative practices and environmental stewardship.

Future Innovations in Airtech Vacuum Pump Technology

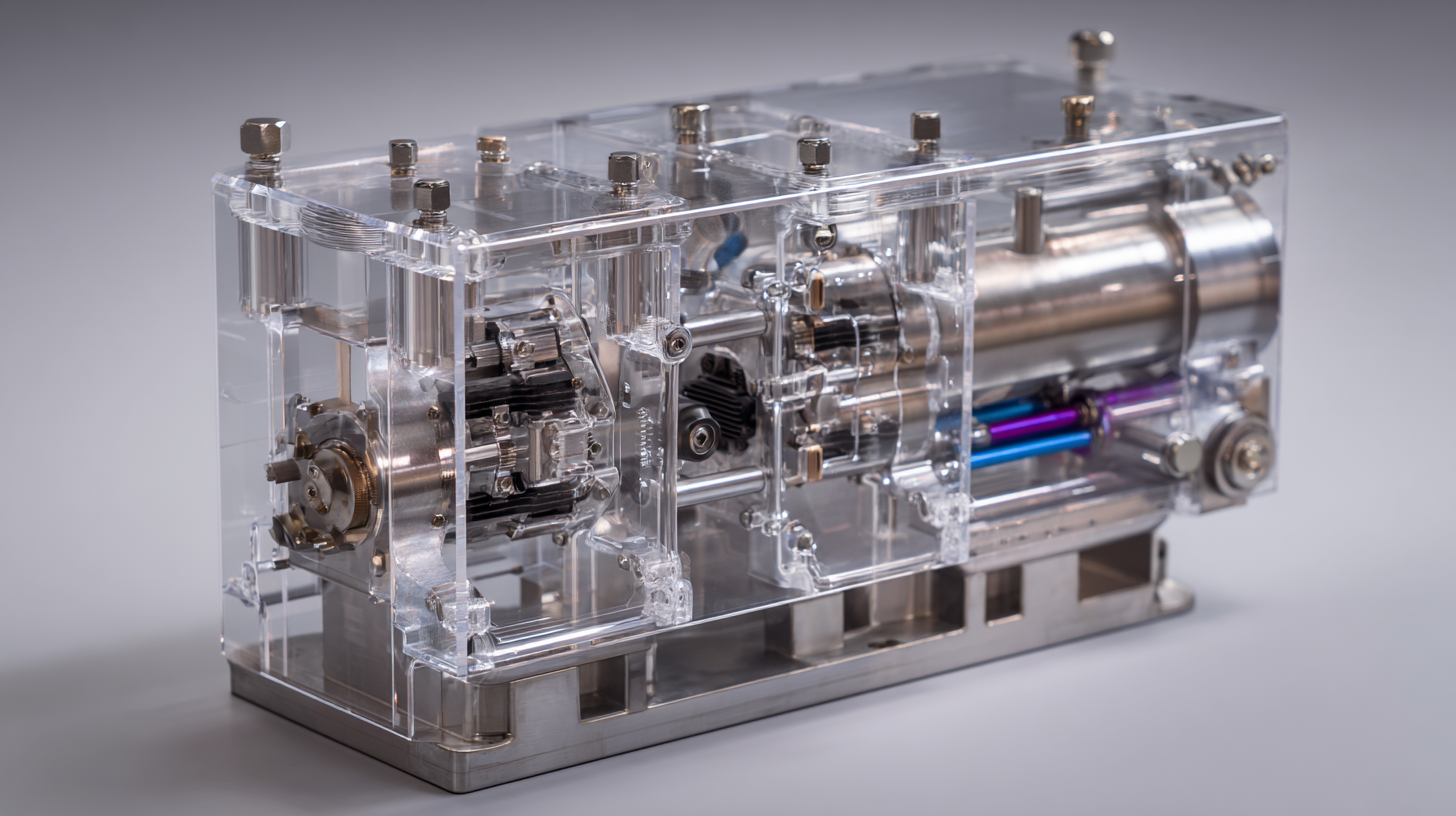

The future of Airtech vacuum pump technology is paving the way for significant advancements in sustainable practices across various industries. With increasing emphasis on energy efficiency and environmental responsibility, innovations in this field are focusing on integrating renewable energy sources and minimizing waste. New designs are emerging that leverage advanced materials and smart automation, promising enhanced performance while reducing the carbon footprint associated with traditional vacuum solutions.

In addition to energy efficiency, the next generation of Airtech vacuum pumps is set to incorporate cutting-edge monitoring and diagnostic tools. These features will allow for real-time feedback and predictive maintenance, optimizing the operation and lifespan of the pumps. As industries seek to comply with stricter regulations and consumer demands for sustainability, the integration of eco-friendly technologies in vacuum pumps becomes not just beneficial but essential. This evolution signifies a shift towards smarter, greener solutions that align with the global sustainability goals, showcasing Airtech's commitment to innovation.

Integration of Airtech Vacuum Pumps in Renewable Energy Systems

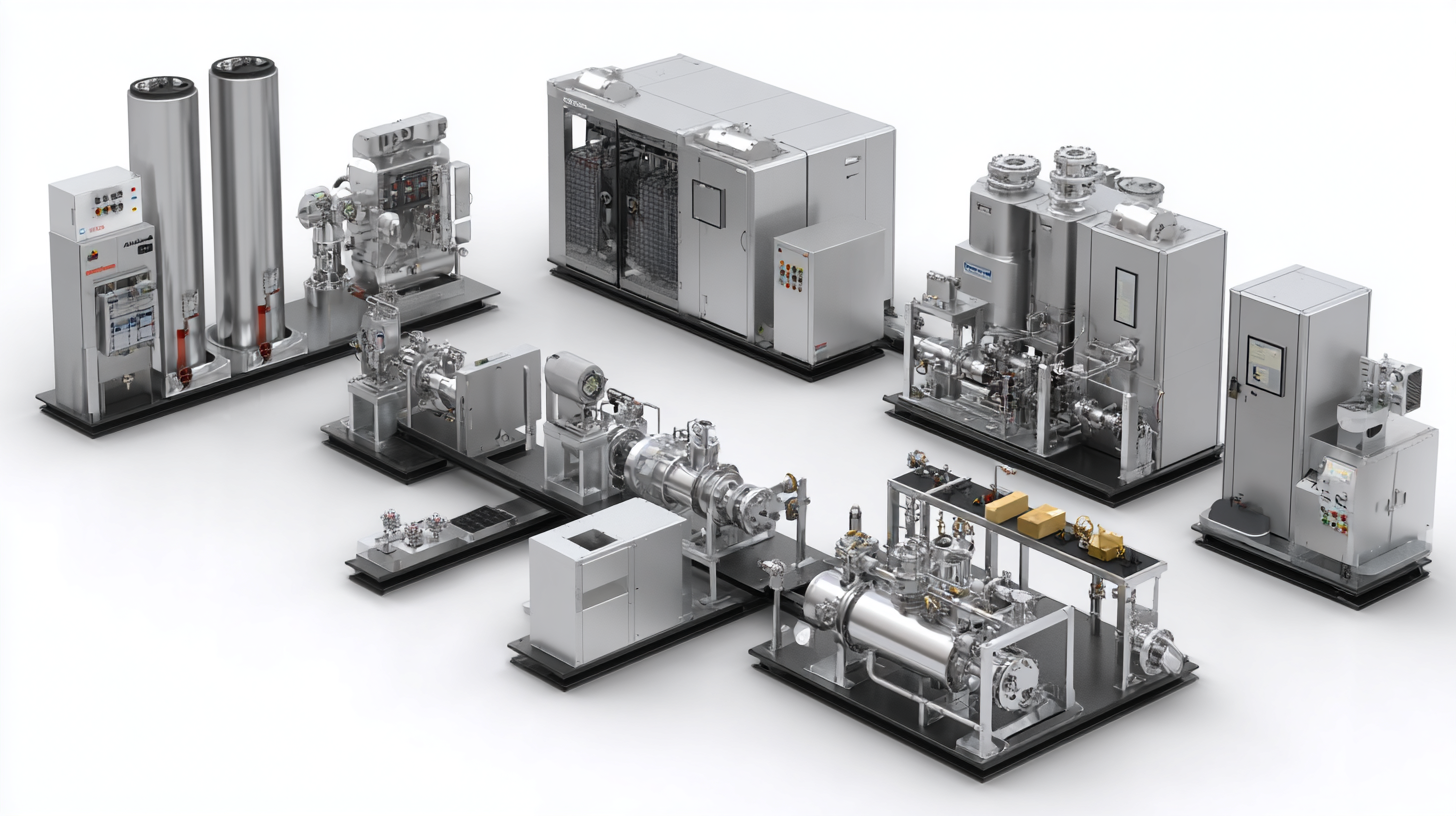

The integration of vacuum pumps into renewable energy systems represents a significant step toward enhancing sustainable technologies. Vacuum pumps, particularly those developed by Airtech, play a crucial role in various renewable applications such as energy storage and efficiency optimization. With the growing need for effective energy management solutions, these pumps facilitate the operation of systems that capture and store energy from intermittent renewable sources, such as solar and wind.

Recent innovations in the renewables sector highlight the potential of integrating advanced technologies to improve energy storage capacities. For instance, a new storage solution that utilizes compressed air technology exemplifies how innovative approaches can complement existing systems. By harnessing air pressure for energy storage, this method presents an efficient alternative that can work alongside traditional vacuum pump systems. As these technologies evolve, the synergy between Airtech vacuum pumps and renewable energy solutions will be pivotal in driving forward the sustainability agenda, ultimately leading to more resilient and responsive energy management frameworks.

Environmental Impact of Airtech Vacuum Pumps in Industrial Applications

Airtech vacuum pumps play a critical role in various industrial applications, particularly as industries strive for sustainability amidst increasing environmental regulations. The environmental impact of these pumps is largely tied to their efficiency in energy consumption and waste management. Recent studies indicate that industrial land expansion can significantly drive economic growth, yet it concurrently exacerbates carbon dioxide emissions—forcing industries to reevaluate their operational practices to mitigate these effects. The need for enhanced resource use efficiency is evident; in industrial setups, increased efficiency in processes using airtech vacuum pumps could reduce carbon footprints by substantial percentages, aligning with the targets outlined in sustainability frameworks.

Moreover, the semiconductor industry's environmental challenges underscore the urgency for cleaner technologies. Airtech vacuum pumps, known for their reliable performance, can enhance process efficiency, potentially leading to lower emissions in comparison with traditional systems. As highlighted in recent reviews, industries that successfully implement efficient wastewater management and resource-use practices see considerable improvements in their environmental impact, suggesting a similar pathway for adopting advanced vacuum technologies. The integration of such systems is vital as industries seek to balance productivity with environmental stewardship, demonstrating that operational excellence need not come at the cost of ecological responsibility.

Efficiency Advances: Digitalization of Airtech Vacuum Pump Systems

The digitalization of Airtech vacuum pump systems marks a significant shift towards enhanced efficiency in sustainable technologies. With continuous advancements in automation and data analytics, these systems have begun to incorporate smart technologies that monitor performance in real time, thereby optimizing energy consumption. According to a recent report by the International Energy Agency, the implementation of smart industrial systems can reduce energy usage by up to 30%. This not only decreases operational costs but also minimizes the carbon footprint, aligning with global sustainability goals.

To fully leverage the benefits of digitalization, it’s crucial for industries to consider the following tips: first, invest in robust data management systems that can analyze performance metrics continuously. Secondly, provide training for staff on new technologies to ensure that they can effectively operate and maintain these advanced systems. Incorporating these practices can lead to significant improvements in both efficiency and sustainability, driving the evolution of Airtech vacuum pumps into a more eco-friendly future.

Additionally, recent studies reveal that vacuum systems equipped with IoT functionalities show an impressive 25% reduction in downtime through predictive maintenance. This reflects a growing trend in the industry to utilize digital tools for proactive management, enhancing operational reliability and sustainability.

Sustainable Manufacturing Practices with Airtech Vacuum Technologies

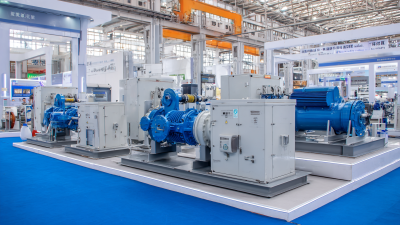

The integration of Airtech vacuum technologies into sustainable manufacturing practices is revolutionizing the way industries approach production. According to a report by the International Energy Agency (IEA), the global manufacturing sector accounts for approximately 21% of total greenhouse gas emissions. By adopting Airtech vacuum pumps, which are designed to optimize energy efficiency and reduce waste, companies can significantly minimize their environmental footprint. For example, studies indicate that vacuum pumps featuring frequency conversion technology can save up to 50% in energy consumption compared to traditional models.

Moreover, Airtech's commitment to sustainable manufacturing is evident in its innovative designs that utilize eco-friendly materials and processes. A recent market analysis by Research and Markets projects that the global vacuum pumps market, driven by advancements in sustainable technology, will reach USD 3.5 billion by 2025, with a notable shift toward greener alternatives. This transition not only aligns with global sustainability goals but also enhances operational efficiency, demonstrating that ecological responsibility and profitability can coexist. Embracing such technologies can empower manufacturers to lead the charge towards a more sustainable future while also capturing the economic advantages associated with reduced operating costs and improved resource management.

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

| Dimension | Data Type | Current Insights | Future Trends |

|---|---|---|---|

| Efficiency Rate | Percentage | 85% | 90-95% |

| Energy Consumption | KWh per unit | 1.5 KWh | 1 KWh |

| Sustainability Index | Rating (1-10) | 7 | 9 |

| Carbon Footprint | CO2 Emissions (kg) | 300 kg/unit | 150 kg/unit |

| Material Recyclability | Percentage | 60% | 80% |

Related Posts

-

Exploring Air Vacuum Innovations at the 138th Canton Fair 2025

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

-

How to Choose the Right Vacuum Industrial Solutions for Your Business Needs

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs