Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

In the landscape of industrial applications, the oil vacuum pump emerges as a pivotal component in various processes, ranging from oil and gas extraction to pharmaceutical manufacturing. According to a report by MarketsandMarkets, the global vacuum pump market is projected to reach USD 4.03 billion by 2025, driven significantly by the growing demand for oil vacuum pumps in diverse sectors. These pumps are integral in creating the necessary vacuum conditions needed for efficient operations, thereby enhancing productivity and operational reliability. Moreover, a recent study by ResearchAndMarkets indicates that the oil vacuum pump market is expected to experience a compound annual growth rate (CAGR) of 5.6% from 2021 to 2026, emphasizing their increasing significance in industrial machinery applications. Understanding the essential role of oil vacuum pumps not only highlights their impact on improving process efficiency but also underscores their importance in supporting the sustainable growth of various industries.

The Fundamental Principles Behind Oil Vacuum Pumps

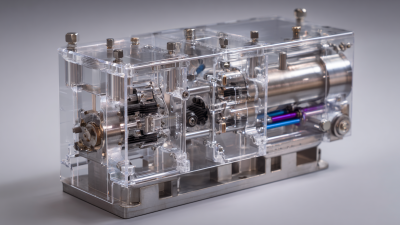

Oil vacuum pumps play a critical role in various industrial applications, primarily based on the fundamental principles of vacuum creation and gas handling. These pumps utilize oil as a sealing and lubricating medium, which enhances their efficiency in achieving deep vacuum levels necessary for processes such as distillation, freeze-drying, and semiconductor manufacturing. The mechanism fundamentally relies on trapping and compressing gas molecules, creating a low-pressure environment that enables efficient material processing.

In recent analyses, the International Energy Agency's Global Methane Tracker 2023 highlights the importance of advanced technologies in reducing emissions within the oil and gas sector. While oil vacuum pumps have traditionally been viewed as essential components for maintaining operational efficiency, their design and operation must also evolve in response to increasing environmental regulations and sustainability goals. According to industry reports, the demand for more efficient and environmentally friendly pumping systems is set to rise, prompting innovations in oil vacuum pump technology that align with broader efforts in emission reduction and energy transitions. As industries navigate these challenges, understanding the mechanical and operational principles of oil vacuum pumps will be crucial for ensuring compliance and enhancing productivity.

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

| Application | Pump Type | Vacuum Level (mbar) | Flow Rate (m³/h) | Typical Usage |

|---|---|---|---|---|

| Food Packaging | Rotary Vane | 10 | 20 | Preserving freshness |

| Chemical Processing | Liquid Ring | 5 | 150 | Solvent recovery |

| Pharmaceuticals | Rotary Vane | 2 | 50 | Vacuum drying |

| Electronics Manufacturing | Scroll Pump | 1 | 30 | Thin film production |

| HVAC Systems | Diaphragm Pump | 15 | 40 | Refrigerant recovery |

Key Benefits of Using Oil Vacuum Pumps in Industry

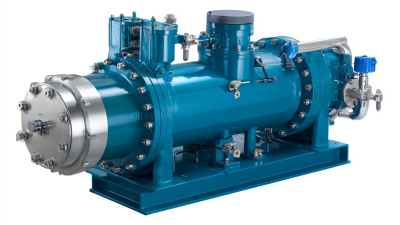

Oil vacuum pumps play a crucial role in various industrial applications, providing several key benefits that enhance operational efficiency. One of the primary advantages is their ability to create a strong vacuum, which is essential for processes such as distillation, drying, and degassing. This capability allows industries to optimize their production processes by improving product quality and reducing processing times. The reliability and performance of oil vacuum pumps make them indispensable in sectors like pharmaceuticals, food processing, and electronics manufacturing.

Additionally, oil vacuum pumps contribute to energy efficiency by significantly minimizing energy consumption during operations. Their design allows for a steady and continuous vacuum, which helps reduce the workload on other equipment, ultimately lowering energy costs. Furthermore, oil vacuum pumps are known for their durability and longevity, resulting in lower maintenance expenses and less frequent replacements. This not only enhances productivity but also ensures a smoother operation within industrial settings, making them a vital component for businesses aiming to maintain a competitive edge.

Common Applications of Oil Vacuum Pumps Across Various Sectors

Oil vacuum pumps play a crucial role in various industrial applications, serving as essential tools across multiple sectors. These pumps are primarily designed to create a vacuum environment, which is vital for processes such as distillation, drying, and chemical processing. Their ability to efficiently remove gases and vapors makes them indispensable in industries like pharmaceuticals, food production, and electronics manufacturing.

Oil vacuum pumps play a crucial role in various industrial applications, serving as essential tools across multiple sectors. These pumps are primarily designed to create a vacuum environment, which is vital for processes such as distillation, drying, and chemical processing. Their ability to efficiently remove gases and vapors makes them indispensable in industries like pharmaceuticals, food production, and electronics manufacturing.

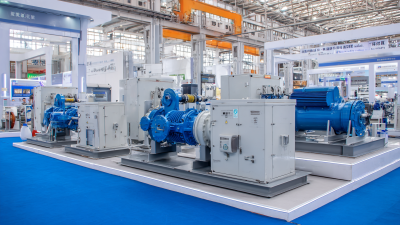

In sectors like semiconductor fabrication and research laboratories, oil vacuum pumps are commonly employed to maintain low-pressure environments required for sensitive processes. Manufacturers increasingly rely on advanced technologies, such as dry-running and liquid ring variants, to enhance energy efficiency and minimize environmental impact. The market for these pumps is expanding, reflecting a CAGR of 3.9% to 7.0% across subcategories, driven by the rising demand for more efficient and eco-friendly vacuum solutions. As industries continue to evolve, the adoption of oil vacuum pumps will remain integral to optimizing operations and maintaining high standards of quality and safety.

Maintenance Best Practices for Oil Vacuum Pumps

Oil vacuum pumps are critical in numerous industrial applications, enabling processes that require the removal of air and moisture from systems. Proper maintenance of these pumps is vital to ensure their longevity and performance efficiency. According to a report by the Vacuum Pump Manufacturers Association, routine maintenance can increase the lifespan of oil vacuum pumps by up to 30%, significantly reducing costs associated with unexpected downtime and replacements.

One of the best practices for maintaining oil vacuum pumps includes regular oil changes. Experts recommend changing the oil every 500 operating hours to prevent the degradation of lubricants and the accumulation of contaminants. Additionally, monitoring the oil's condition through periodic analysis can help operators detect potential issues before they escalate. Moreover, keeping the pump’s seals and filters clean is essential to avoid leaks and maintain optimal vacuum levels, which have been shown to enhance overall system efficiency by 15% according to the International Pump User’s Group findings.

Implementing a comprehensive maintenance schedule will not only improve the performance of oil vacuum pumps but also ensure compliance with regulatory standards in various industries. Regular training for personnel on maintenance best practices is essential, as it equips them with the knowledge to identify early signs of wear and maintain the equipment effectively.

Challenges and Solutions in Implementing Oil Vacuum Systems

In industrial applications, oil vacuum pumps play a crucial role in maintaining efficiency and operational integrity. However, integrating these systems presents several challenges. One primary issue is the risk of oil contamination, which can compromise the vacuum's efficiency and impact the quality of the end product. This necessitates rigorous filtration systems and regular maintenance to ensure that the oil used in the vacuum process remains free of impurities.

Another significant challenge involves the energy consumption associated with oil vacuum pumps. These systems can be power-intensive, leading to increased operational costs. Companies are increasingly seeking solutions such as advanced pump designs that offer improved energy efficiency. Additionally, implementing smart technologies that monitor energy usage and optimize performance can help mitigate these costs while ensuring that the vacuum systems operate at peak performance levels. By addressing these challenges through innovative solutions, industries can enhance the reliability and longevity of their oil vacuum systems.

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

This chart illustrates key performance metrics of oil vacuum pumps used in industrial applications. It includes efficiency percentage, operating costs, maintenance frequency, and lifespan, which are crucial for understanding the challenges and solutions in implementing oil vacuum systems.

Related Posts

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals

-

Unlocking Efficiency: The Science Behind Dry Rotary Vane Vacuum Pumps and Their Industry Applications

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs