Unlocking Efficiency: The Science Behind Dry Rotary Vane Vacuum Pumps and Their Industry Applications

In today's fast-paced industrial landscape, efficiency is paramount, and the dry rotary vane vacuum pump has emerged as a key player in achieving this goal. This innovative technology, characterized by its ability to produce high-quality vacuum without the use of liquids, not only enhances operational reliability but also significantly reduces maintenance costs. As various industries, from pharmaceuticals to food processing, increasingly seek to optimize their processes, understanding the science behind dry rotary vane vacuum pumps is crucial. This guide aims to explore the underlying principles of these pumps, their unique advantages, and the diverse applications where they are making a significant impact. By unlocking the efficiency that dry rotary vane vacuum pumps offer, businesses can streamline operations, improve product quality, and stay competitive in a challenging market.

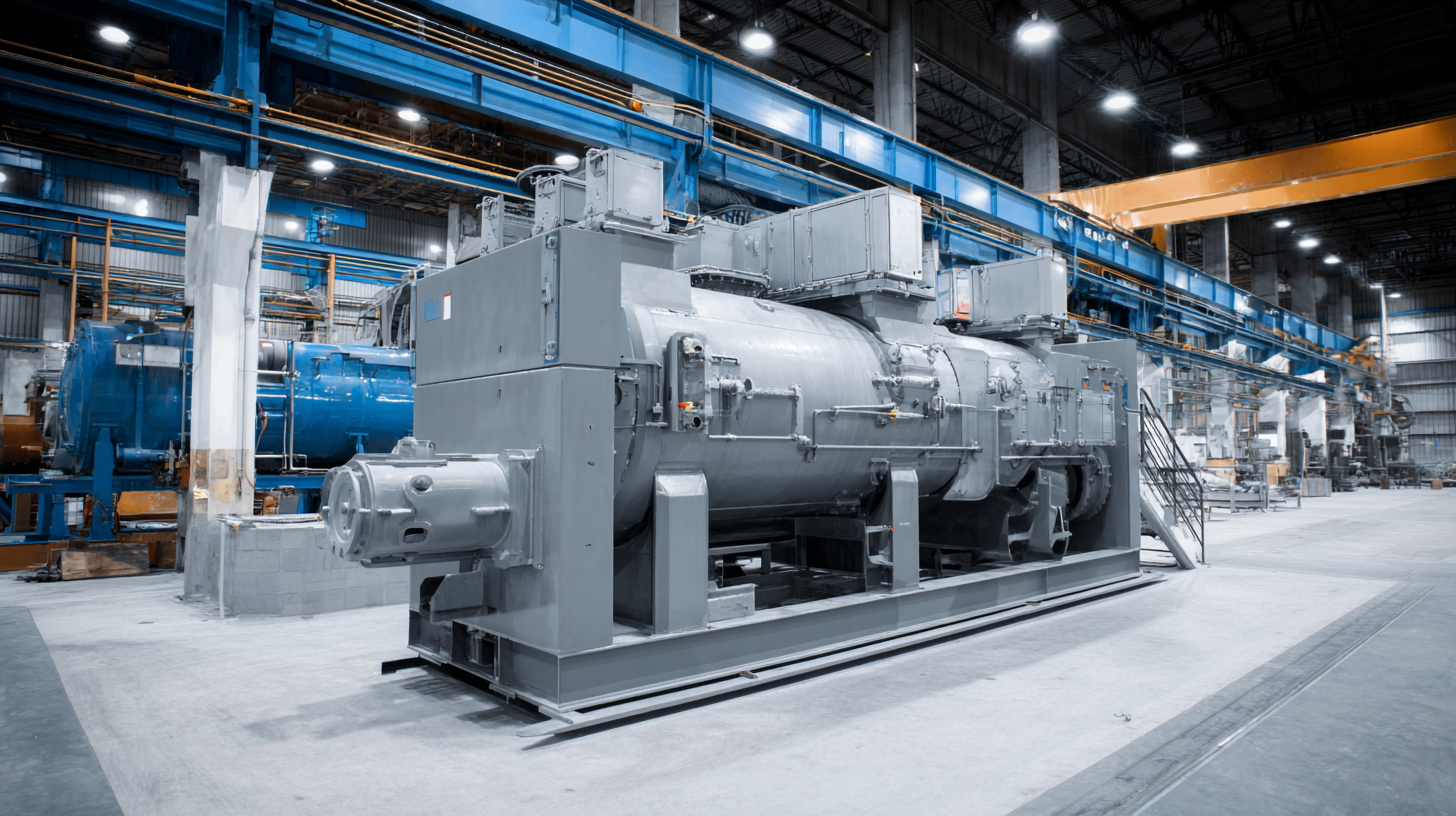

Understanding Dry Rotary Vane Vacuum Pumps: Technology and Operation

Dry rotary vane vacuum pumps play a pivotal role in various industrial applications, particularly in sectors where efficient and reliable vacuum generation is crucial. The latest innovations in this technology, such as energy-efficient designs, are significantly impacting industries. For instance, recent advancements in dry vacuum technology have shown that energy savings can increase by up to 25%. This not only reduces operational costs but also enhances the sustainability of industrial processes.

The global market for dry vacuum pumps is witnessing robust growth, driven largely by the semiconductor and electronics industries. By 2034, the market is expected to exhibit a CAGR of over 5.2%, reaching a valuation of approximately USD 7.5 billion. This growth is complemented by the ongoing demand for advanced technologies in manufacturing processes, where precise vacuum control is essential. The application of dry rotary vane vacuum pumps in metal heat treatment and other critical operations highlights their versatility and effectiveness in meeting modern industrial requirements. As sectors continue to evolve, the importance of efficient vacuum technology will undoubtedly increase, emphasizing the need for ongoing innovation in dry rotary vane designs.

Unlocking Efficiency: The Science Behind Dry Rotary Vane Vacuum Pumps and Their Industry Applications

| Parameter | Description | Applications |

|---|---|---|

| Flow Rate | The volume of air removed by the pump, typically measured in cubic meters per hour (m³/h). | Used in packaging, food processing, and pharmaceuticals. |

| Ultimate Vacuum | The maximum vacuum level achieved, typically measured in millibar (mbar). | Important in semiconductor manufacturing and research laboratories. |

| Power Consumption | The amount of energy used by the pump, measured in kilowatts (kW). | Relevant for cost-efficiency in large-scale industrial operations. |

| Noise Level | Measured in decibels (dB), indicating the operational noise of the pump. | Consideration for use in enclosed workspaces and laboratories. |

| Maintenance Requirements | Frequency and type of maintenance needed to ensure optimal performance. | Critical for industries like automotive and aerospace. |

| Operating Temperature | The range of temperatures in which the pump can safely operate. | Relevant in chemical processing and environmental applications. |

Key Advantages of Choosing Dry Rotary Vane Vacuum Pumps in Industry

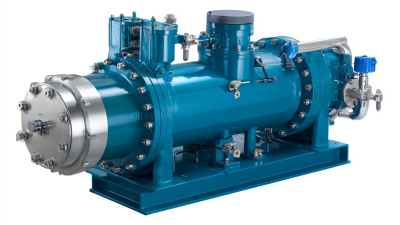

Dry rotary vane vacuum pumps are increasingly becoming the preferred choice in various industrial applications due to their key advantages over traditional pumps. One of the most significant benefits is the lack of oil contamination, which is crucial for industries like pharmaceuticals and food processing. According to a report by Research and Markets, the global market for oil-free vacuum pumps is projected to reach $3.5 billion by 2026, driven by the growing demand for clean and efficient production processes. This trend underscores the importance of maintaining product purity, as even minor contamination can lead to significant economic losses.

Dry rotary vane vacuum pumps are increasingly becoming the preferred choice in various industrial applications due to their key advantages over traditional pumps. One of the most significant benefits is the lack of oil contamination, which is crucial for industries like pharmaceuticals and food processing. According to a report by Research and Markets, the global market for oil-free vacuum pumps is projected to reach $3.5 billion by 2026, driven by the growing demand for clean and efficient production processes. This trend underscores the importance of maintaining product purity, as even minor contamination can lead to significant economic losses.

Another advantage of dry rotary vane vacuum pumps is their energy efficiency. A study from the Compressed Air and Gas Institute (CAGI) highlights that these pumps can reduce energy consumption by up to 30% compared to oil-lubricated systems. This reduction not only lowers operational costs but also contributes to sustainability goals, as businesses are under increasing pressure to minimize their carbon footprint. As industries continue to prioritize efficiency and environmental responsibility, integrating dry rotary vane vacuum pumps into operations can be a strategic move that aligns with modern operational standards.

Common Applications of Dry Rotary Vane Vacuum Pumps Across Various Sectors

Dry rotary vane vacuum pumps are essential in various industrial applications, offering reliable performance without the need for oil lubrication. Their design allows for the efficient handling of gases and vapors, making them ideal for sectors such as

pharmaceuticals,

food processing, and

semiconductor manufacturing. According to a report by MarketsandMarkets, the global vacuum pump market is expected to reach approximately $7 billion by 2026, with

dry vacuum pumps accounting for a significant portion of this growth due to their increasing adoption in cleanroom applications and environmental compliance.

Dry rotary vane vacuum pumps are essential in various industrial applications, offering reliable performance without the need for oil lubrication. Their design allows for the efficient handling of gases and vapors, making them ideal for sectors such as

pharmaceuticals,

food processing, and

semiconductor manufacturing. According to a report by MarketsandMarkets, the global vacuum pump market is expected to reach approximately $7 billion by 2026, with

dry vacuum pumps accounting for a significant portion of this growth due to their increasing adoption in cleanroom applications and environmental compliance.

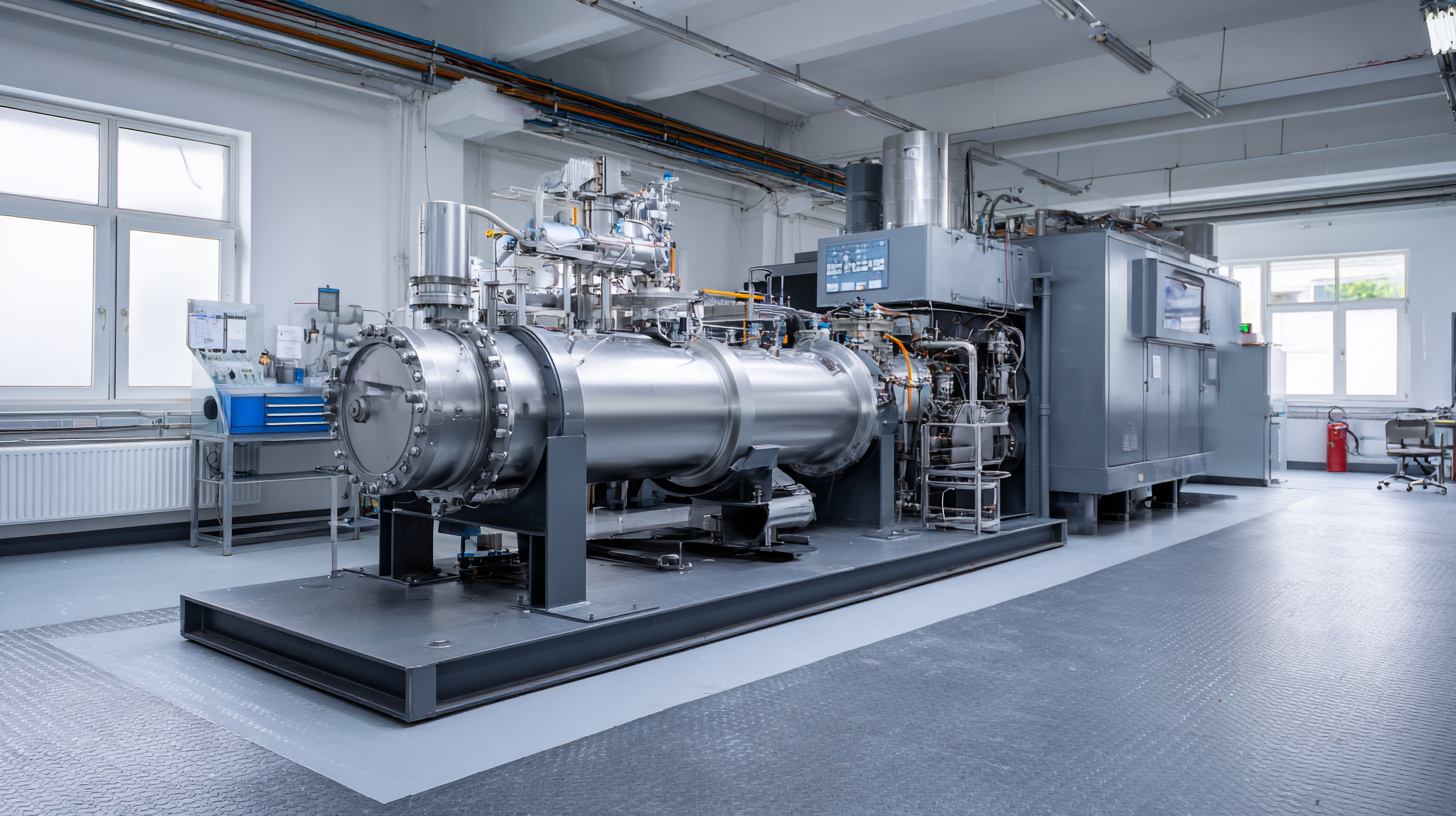

In the pharmaceutical industry, where contamination control is critical, dry rotary vane vacuum pumps are widely used for processes such as freeze drying and packaging. Their ability to achieve high levels of vacuum and maintain purity ensures the integrity of pharmaceutical products. Additionally, in the food processing sector, these pumps facilitate vacuum packing, enhancing food preservation and shelf-life. As highlighted in a research study by Grand View Research, the food and beverage industry is predicted to witness significant growth, further driving the demand for efficient vacuum solutions.

Moreover, in semiconductor manufacturing, where precision is paramount, dry rotary vane vacuum pumps support processes such as wafer fabrication and coating. The surge in electronic device production, projected by Statista to reach 1.5 trillion units by 2025, emphasizes the need for advanced vacuum technologies that ensure product quality and operational efficiency. These pumps enhance productivity while minimizing risks associated with oil backstreaming, making them an indispensable asset across multiple sectors.

Maintenance Tips for Maximizing the Lifespan of Vacuum Pumps

Dry rotary vane vacuum pumps are known for their reliability and efficiency across various industries, but to maximize their lifespan, proper maintenance is essential. According to a recent report by the Vacuum Technology Association, regular maintenance can extend the operational life of vacuum pumps by up to 30%. Key tasks include routine inspections of the vanes and seals, checking for wear and tear, and ensuring the system is free from contamination.

Another critical aspect of maintenance is monitoring the pump’s operating conditions. Keeping an eye on temperature and pressure levels helps detect early signs of malfunction, allowing for timely interventions. A study published in the Journal of Vacuum Science revealed that implementing a proactive maintenance schedule can significantly reduce downtime and improve overall productivity by nearly 25%. By prioritizing these maintenance strategies, industries can not only enhance the efficiency of their dry rotary vane vacuum pumps but also optimize their investment in vacuum technology.

Innovative Trends in Dry Rotary Vane Technology for Enhanced Efficiency

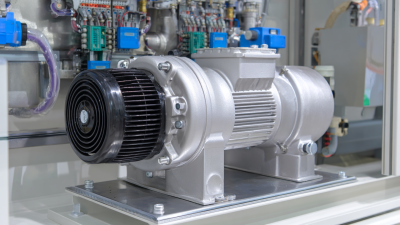

Innovative trends in dry rotary vane technology have revolutionized the vacuum pump industry, emphasizing increased efficiency and sustainability. Recent advancements focus on optimizing the design of the vanes and the rotor mechanism, leading to improved energy consumption and performance. Manufacturers are now employing high-quality materials that reduce friction and wear, thus extending the lifespan of the pumps while maintaining consistent vacuum levels. These technological enhancements also minimize maintenance requirements, allowing industries to focus on their core operations with less downtime.

Moreover, the integration of smart technology and IoT into dry rotary vane vacuum pumps is on the rise. Real-time monitoring systems provide critical data on performance metrics, enabling users to predict maintenance needs and optimize operational conditions. This trend not only enhances the efficiency of the vacuum pumps but also aids in reducing environmental impact by lowering energy consumption. As industries increasingly prioritize sustainability, the adoption of these innovative dry rotary vane technologies will play a significant role in meeting both operational and environmental goals.

Efficiency Comparison of Dry Rotary Vane Vacuum Pumps Across Industries

This chart illustrates the efficiency ratings of dry rotary vane vacuum pumps across various industries, showcasing the adaptability and efficiency advancements in this technology.

Related Posts

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

How to Choose the Right Vacuum Industrial Solutions for Your Business Needs

-

Exploring Air Vacuum Innovations at the 138th China Import and Export Fair 2025