Exploring the Efficiency of Oil Vacuum Pumps: The Future of Industrial Sustainability

The industrial sector is constantly evolving, and one of the critical components driving this change is the oil vacuum pump. As industries seek ways to enhance productivity while minimizing their environmental impact, the efficiency of oil vacuum pumps comes under scrutiny. These pumps play a pivotal role in various industrial applications, from packaging to chemical processing, by creating the necessary vacuum conditions for optimal operations. With the pressing challenge of sustainability, understanding the performance and technological advancements of oil vacuum pumps is crucial. This exploration delves into how innovations in design and operation can lead to increased energy efficiency, reduced emissions, and improved longevity, paving the way for a more sustainable industrial future. The insights gained will not only inform best practices but also highlight the essential role of oil vacuum pumps in achieving ecological and economic balance in industrial operations.

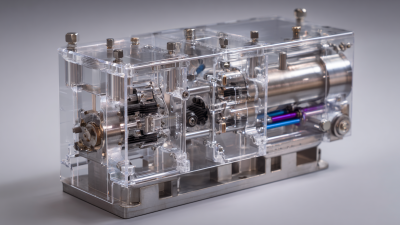

Understanding the Mechanism of Oil Vacuum Pumps in Industrial Applications

Oil vacuum pumps play a crucial role in various industrial applications by creating a controlled environment that enhances operational efficiency. These pumps work by removing air and other gases from a sealed volume, allowing for processes that require reduced pressure. Understanding their mechanism involves recognizing that they operate on principles of fluid dynamics, utilizing either liquid or dry materials to achieve vacuum levels designed to meet specific requirements. This makes them vital in manufacturing, food processing, and even pharmaceuticals.

Tips: When selecting an oil vacuum pump, consider the type of application, required vacuum level, and material compatibility. Regular maintenance is also essential to ensure longevity and optimal performance of the pump, which ultimately leads to better sustainability practices within your operation.

As industries increasingly focus on sustainability, the efficiency of oil vacuum pumps cannot be overstated. By investing in advanced technology and understanding the operational mechanics, organizations can optimize their processes, reduce waste, and enhance environmental responsibility. Moreover, the growing market for vacuum pumps indicates a trend towards innovative solutions that not only improve efficiency but also contribute to sustainability in industrial applications.

Oil Vacuum Pumps Efficiency in Industrial Applications

This bar chart illustrates the efficiency of oil vacuum pumps based on their application in various industrial sectors. The data shows the average efficiency rating on a scale of 1 to 100 for different applications. Higher efficiency ratings indicate a more sustainable operation in industrial settings.

Assessing the Environmental Impact of Traditional vs. Oil Vacuum Pumps

The environmental impact of traditional oil vacuum pumps compared to their oil-less counterparts is a pivotal consideration in the quest for industrial sustainability. Traditional oil vacuum pumps often rely on a significant amount of oil for lubrication and cooling, which can lead to leaks and contamination of the surrounding environment. Recent assessments of conventional methods, such as the acid-clay method for reclaiming waste crankcase lubricating oil, show that while these techniques can effectively re-refine oil, they still pose challenges related to waste management and emissions that undermine their sustainability.

The environmental impact of traditional oil vacuum pumps compared to their oil-less counterparts is a pivotal consideration in the quest for industrial sustainability. Traditional oil vacuum pumps often rely on a significant amount of oil for lubrication and cooling, which can lead to leaks and contamination of the surrounding environment. Recent assessments of conventional methods, such as the acid-clay method for reclaiming waste crankcase lubricating oil, show that while these techniques can effectively re-refine oil, they still pose challenges related to waste management and emissions that undermine their sustainability.

In contrast, oil vacuum pumps designed with advanced technology not only minimize environmental impact but also enhance operational efficiency. The switch to these innovative pumps reduces reliance on oil, thus decreasing the risk of spills and contamination. Furthermore, they align with global trends towards sustainable industrial practices as highlighted by recent discussions on oil resource management and lifecycle assessments of various oil extraction and processing methods.

Tips for businesses considering a transition to oil vacuum pumps include evaluating the total lifecycle costs and benefits, exploring the available technologies that minimize environmental impact, and initiating a thorough assessment of carbon emissions associated with current practices. By adopting sustainable technologies, industries can not only ensure compliance with environmental regulations but also contribute positively to their corporate social responsibility goals.

Evaluating Energy Efficiency: Cost Benefits of Oil Vacuum Pumps

Oil vacuum pumps play a crucial role in enhancing energy efficiency within various industrial processes. Their ability to maintain a vacuum environment helps optimize operations, reducing energy consumption significantly. When evaluating the cost benefits of these pumps, it becomes evident that while the initial investment may be higher compared to other systems, the long-term savings on energy bills and maintenance can offset this cost. Many industries find themselves reassessing their pump choices as sustainability becomes a priority.

**Tips for Choosing an Oil Vacuum Pump:**

1. Assess your specific application to determine the optimal pump size and capacity.

2. Look for energy-efficient models that provide the best performance with lower power consumption.

3. Consider the total cost of ownership, including energy costs, maintenance, and potential downtime, to make an informed decision.

By integrating oil vacuum pumps into their operations, companies are not only increasing their efficiency but also taking substantial steps toward sustainability. As industries strive to minimize their environmental impact, selecting the right pump can contribute significantly to a greener future.

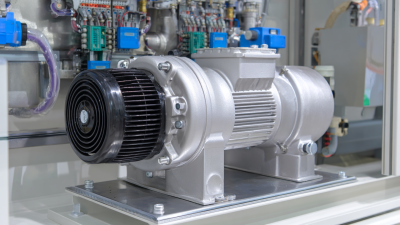

Innovations in Oil Vacuum Pump Technology for Sustainable Practices

The advancement of oil vacuum pump technology is pivotal in driving sustainability across various industrial sectors. Innovations in this field are focusing on enhancing efficiency while minimizing environmental impact. For instance, modern designs incorporate energy-efficient motors and improved sealing systems that significantly reduce energy consumption and emissions during operation. As industries strive to align with stricter environmental regulations, such innovations are not merely beneficial but essential for compliance and operational effectiveness.

Additionally, the growing market for vacuum pumps reflects a broader trend towards sustainable industrial practices. The European vacuum pumps market is projected to expand rapidly, indicating a robust demand for technologies that support sustainability goals. Innovations such as smart control systems and predictive maintenance capabilities are being developed to optimize performance and extend the lifespan of these pumps, further contributing to resource conservation. These trends underline the importance of continuous innovation in oil vacuum pump technology as a key driver of sustainable practices across industries.

Exploring the Efficiency of Oil Vacuum Pumps: The Future of Industrial Sustainability

| Technology Type | Efficiency (%) | Power Consumption (kW) | Noise Level (dB) | Lifespan (Years) | Sustainability Rating |

|---|---|---|---|---|---|

| Rotary Vane | 85 | 7.5 | 70 | 10 | B |

| Liquid Ring | 90 | 8.0 | 68 | 12 | A |

| Screw Vacuum | 92 | 9.0 | 66 | 15 | A+ |

| Scroll Vacuum | 88 | 6.5 | 72 | 14 | B+ |

Future Trends: Integrating Oil Vacuum Pumps into Eco-Friendly Industrial Solutions

The integration of oil vacuum pumps into eco-friendly industrial solutions represents a significant step forward in promoting sustainability within various manufacturing processes. As industries increasingly face pressure to minimize their environmental impact, oil vacuum pumps are evolving to become more energy-efficient and less harmful to the ecosystem. These advanced systems can effectively handle the extraction and recycling of oils, reducing waste and pollution while enhancing overall operational efficiency.

Future trends indicate that the development of hybrid and electric-powered oil vacuum pumps will gain traction, aligning with global efforts to adopt cleaner technologies. Manufacturers are actively investing in research and innovation to create pumps that not only fulfill traditional roles but also meet stringent environmental regulations. By prioritizing the use of biodegradable lubricants and energy-efficient designs, industries can transition towards more sustainable practices, paving the way for a greener future in industrial applications.

Related Posts

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Exploring Air Vacuum Innovations at the 138th Canton Fair 2025

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

Revolutionizing Industries with Tailored Custom Engineering Solutions