How to Choose the Right Suction Pump for Your Specific Needs

Selecting the appropriate suction pump for your specific needs is a critical decision that can significantly impact operational efficiency and productivity. According to a report by MarketsandMarkets, the global market for suction pumps is projected to reach $4.5 billion by 2025, driven by increasing demand across various industries such as healthcare, wastewater management, and construction.

Suction pumps are essential for various applications, from medical procedures to industrial processes, highlighting the importance of understanding the specific requirements of your operation. Factors such as flow rate, viscosity of the fluids being handled, and the environment in which the pump will operate must all be carefully considered to ensure optimal performance. In this guide, we will explore the key aspects to evaluate when choosing the right suction pump, empowering you to make informed decisions that align with your operational goals.

Understanding the Basics of Suction Pumps and Their Applications

When selecting the right suction pump for your specific needs, it is essential to understand the fundamental principles behind suction pump operation and various applications. Suction pumps are versatile devices used in a range of sectors, including chemical laboratories, water supply systems, and renewable energy applications. Understanding the basics can help you determine the best suction pump for your requirements.

**Tips:** First, consider the type of fluid you will be pumping. Different pumps are designed for specific fluids, such as water, chemicals, or slurries. For example, newer models, like recirculating water vacuum pumps, are specially designed for laboratory use with a compact footprint and advanced features. Second, evaluate the pump's operational principles by ensuring it operates within its preferred operating region (POR) to maintain performance and reliability.

When assessing suction pumps, also take into account their energy efficiency and environmental impact. The integration of renewable energy sources in pump systems, such as solar-powered water pumping solutions, showcases modern advancements in this field. Selecting a pump that aligns with both your operational needs and sustainable practices will enhance both efficiency and reliability in your applications.

Identifying Your Specific Requirements and Use Cases for Suction Pumps

When selecting the right suction pump, it is crucial to first identify your specific requirements and use cases. Consider the applications where the pump will be utilized, such as wastewater management, industrial cleaning, or medical scenarios. Each use case demands different specifications; for instance, a pump for industrial use may need higher flow rates and durability, while one for medical applications must adhere to strict hygiene standards and precise operational controls.

In addition to understanding the operational context, it’s important to recognize the environmental factors and contaminants involved. Advanced analytical methods can help determine the types of pollutants in water and wastewater, directly influencing pump selection. Furthermore, integrating machine learning technology can enhance the efficiency of suction systems by predicting maintenance needs and optimizing performance based on real-time data. This proactive approach not only ensures effective operation but also prolongs the life cycle of the equipment, making it an essential consideration for those looking to maximize their investment in suction technology.

How to Choose the Right Suction Pump for Your Specific Needs

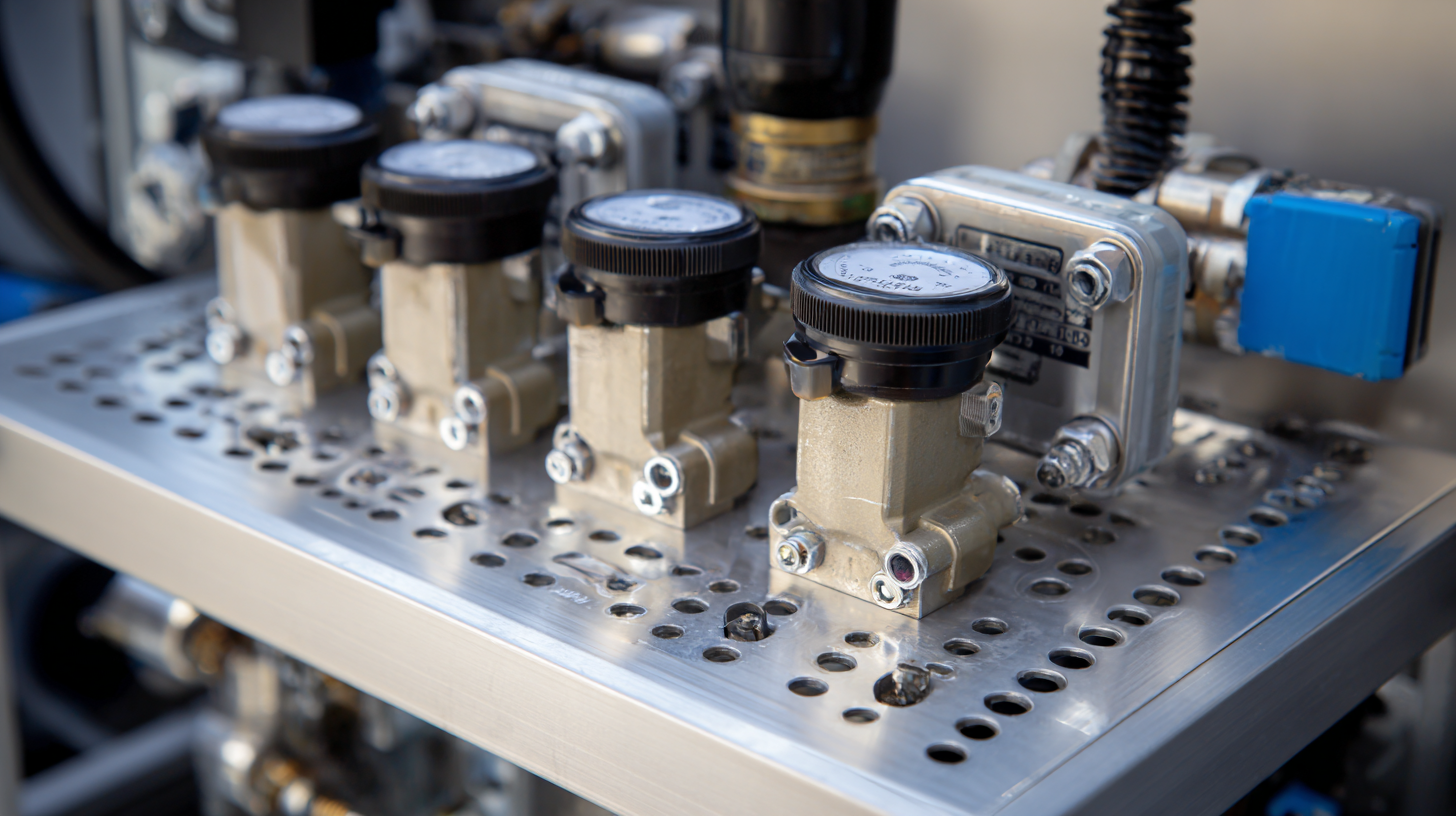

Comparing Different Types of Suction Pumps and Their Features

When choosing a suction pump, understanding the various types available is essential for meeting your specific needs. There are primarily three categories of suction pumps: diaphragm pumps, rotor pumps, and peristaltic pumps. Diaphragm pumps are perfect for handling abrasive and corrosive fluids, thanks to their durable construction. Rotor pumps, on the other hand, excel in high-viscosity applications due to their ability to maintain a steady flow. Meanwhile, peristaltic pumps are ideal for sterile applications, as the fluid only comes into contact with tubing, reducing the risk of contamination.

Tips: Consider the fluid characteristics you will be handling, as this will guide you in selecting the right material for the pump. For instance, if you are pumping corrosive substances, opt for pumps made of polypropylene or stainless steel. Additionally, evaluate the flow rate requirements and what power source is most convenient for your operations.

While comparing suction pumps, it's also important to take note of their maintenance needs. Some pumps may require more frequent servicing than others, which can affect long-term operational costs. Take time to research user reviews and technical specifications to ensure that the pump you choose not only fits your immediate needs but is also durable and reliable in the long run.

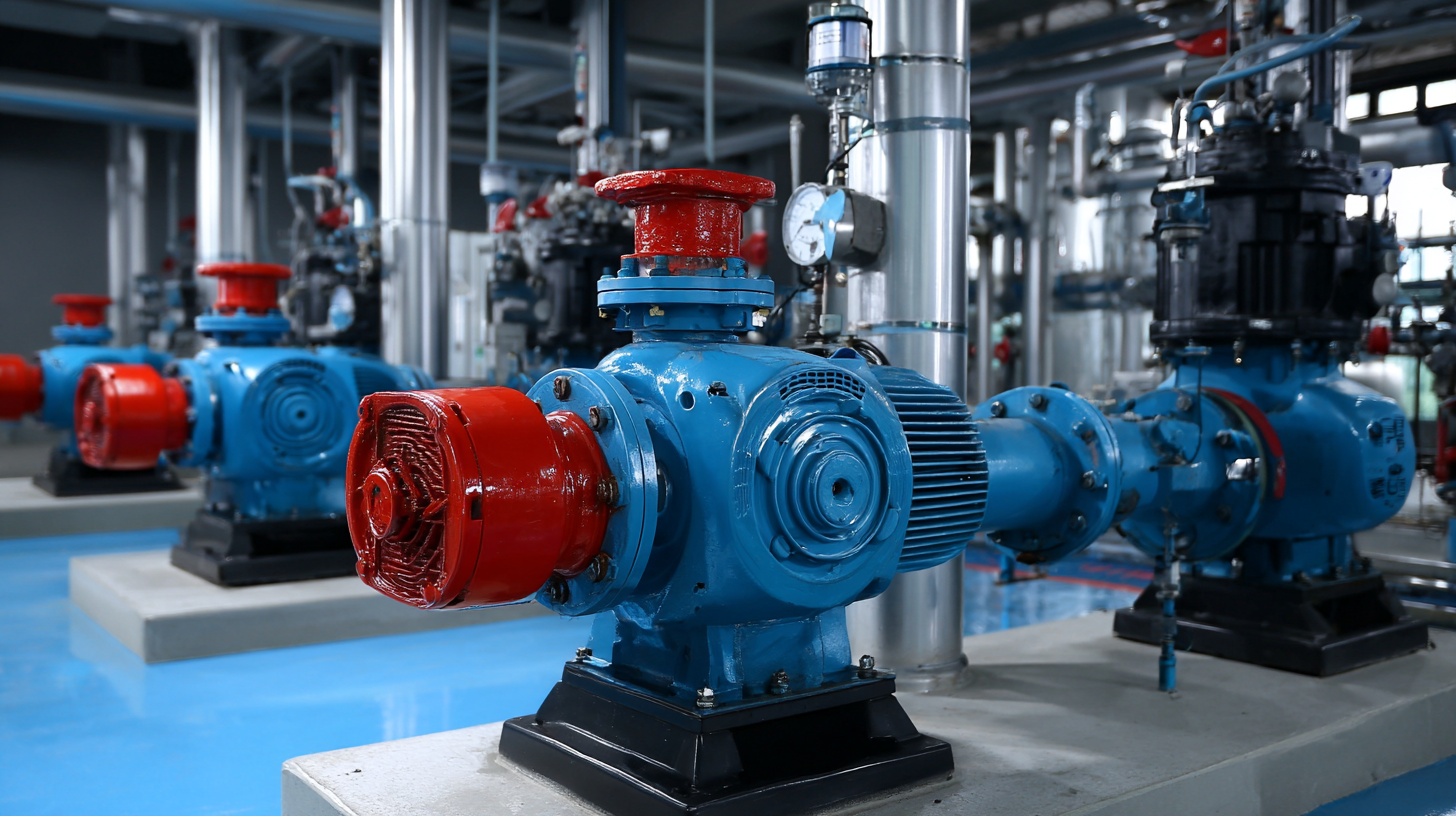

Evaluating Performance Metrics: Flow Rate, Vacuum Level, and Power Consumption

When selecting a suction pump tailored to your specific needs, evaluating performance metrics such as flow rate, vacuum level, and power consumption becomes crucial. The flow rate indicates the volume of fluid the pump can handle in a given timeframe, directly impacting the efficiency of processes like direct air capture (DAC). Innovative approaches such as Catalytic Membrane Vacuum Regeneration (C-MVR) demonstrate the importance of integrating energy-efficient designs that optimize flow rates while maintaining sustainable energy sources.

Equally significant is the vacuum level, which measures the pump's ability to create a pressure differential necessary for various applications. For example, advancements in vacuum evaporation technology highlight the role of optimizing vacuum levels for environmental applications like anaerobic digestate management in wastewater treatment. Identifying the appropriate balance between vacuum level and power consumption is essential, as it not only enhances system performance but also supports the desire for greener, more efficient processes in sectors ranging from desalination to carbon capture. Efficient suction pumps can thus facilitate advancements in technology while meeting the growing demand for renewable compatibility.

How to Choose the Right Suction Pump for Your Specific Needs

| Pump Type | Flow Rate (L/min) | Vacuum Level (mbar) | Power Consumption (W) |

|---|---|---|---|

| Diaphragm Pump | 10 | 50 | 150 |

| Gear Pump | 20 | 100 | 300 |

| Rotary Vane Pump | 30 | 10 | 500 |

| Piston Pump | 15 | 30 | 200 |

| Scroll Pump | 40 | 5 | 700 |

Tips for Maintenance and Troubleshooting Common Suction Pump Issues

When selecting a suction pump, maintaining its optimal performance is crucial. One common issue that can arise in pump systems is air entrainment, which can lead to significant operational inefficiencies. To reduce or eliminate air entrainment, ensure that the suction side of your pump is properly designed and maintained. This includes checking for leaks and ensuring that the pump is adequately submerged in the fluid being pumped. Regular inspections of the inlet and outlet valves can also help prevent air from entering the system.

Cavitation is another critical issue that often affects suction pumps. It occurs when vapor bubbles form in the fluid due to low pressure, and their subsequent collapse can cause severe damage to the pump. To avoid cavitation, maintain proper fluid levels and ensure that the pump operates within its specified parameters. Implementing regular maintenance routines, such as cleaning filters and monitoring pump speed, is essential for early detection and resolution of common problems. Proper training on troubleshooting these issues can save time and costs associated with repairs.