How to Choose the Best Oil Free Vacuum Pump for Your Needs?

Choosing the right oil free vacuum pump can significantly impact your operations. An oil free vacuum pump provides a clean and efficient solution for various applications. These pumps eliminate the risk of oil contamination, which is crucial in sensitive environments.

When selecting an oil free vacuum pump, consider your specific needs. Think about factors like the required vacuum level, flow rate, and noise levels. Each application has different demands, and not all pumps are created equal. You might feel overwhelmed by the options available. Some might claim to be the best, but their performance may not meet your expectations.

It’s important to evaluate your requirements thoroughly. Don't hesitate to ask for demonstrations or seek recommendations. Investigating the brand reputation is key. Each option can greatly affect your decision. Finding the perfect oil free vacuum pump is a journey worth taking, albeit sometimes frustrating.

Understanding the Basics of Oil-Free Vacuum Pumps

Oil-free vacuum pumps are gaining traction in various industries due to their unique advantages. Understanding their basic functionality is crucial. These pumps operate without oil lubrication, reducing the risk of contamination. This makes them ideal for applications in pharmaceuticals, food processing, and semiconductor manufacturing. According to industry reports, oil-free vacuum pumps can achieve a vacuum level of up to 10^-3 mbar. This is sufficient for many sensitive applications.

One notable feature of oil-free vacuum pumps is their energy efficiency. A report by the American Society of Mechanical Engineers highlights that oil-free systems can save up to 30% more energy compared to traditional pumps. They also require less maintenance, reducing overall operational costs. However, the initial investment can be higher for oil-free models. It's essential to weigh long-term savings against upfront expenditures.

Noise levels can also be a consideration. Many oil-free vacuum pumps operate more quietly, often producing under 60 dB. This is advantageous for laboratory and hospital environments. Yet, some models exhibit inconsistent performance, especially when handling varying loads. Users often report needing to adjust settings frequently, which can be frustrating. It's clear that while oil-free vacuum pumps offer many benefits, careful selection is necessary to align with specific needs.

Oil-Free Vacuum Pump Performance Comparison

Identifying Your Specific Application Requirements

Choosing the right oil-free vacuum pump starts with understanding your application. Different tasks require different specifications. For example, lab work demands clean operations to avoid contamination. In contrast, industrial uses may focus on efficiency and durability. Knowing the specifics can save you time and money.

Consider the environment in which the pump will operate. Some applications need a constant vacuum level. Others might tolerate fluctuation. Understanding whether you need high vacuum or rough vacuum is crucial. You may also need to evaluate the pumping speed. Too slow can hinder processes, while too fast might not be necessary. Sometimes, an off-the-shelf solution doesn’t fit perfectly.

Also, reflect on maintenance requirements. Oil-free pumps generally require less upkeep. However, some still need regular checks for optimal performance. Ignoring this could lead to unexpected downtimes. Each application has its intricacies. Balancing performance, efficiency, and upkeep can be challenging. What works for one may not work for another. Take the time to assess your specific needs before making a decision.

Key Features to Consider in an Oil-Free Vacuum Pump

Choosing the right oil-free vacuum pump requires careful consideration of several key features. One important factor is the pump's performance level. Look for a model that provides adequate suction power for your specific applications. The ideal pump should effectively remove air and gases without leaving any residue.

Another aspect to consider is noise level. Some oil-free vacuum pumps can be quite loud. Operating a noisy pump can lead to discomfort in a workspace. Pay attention to the decibel rating; quieter models are often more desirable in sensitive environments. You might also want to check the design and portability.

Maintenance needs can vary significantly among different pumps. Some models may require more frequent upkeep than others. Evaluate how easy it is to clean or replace parts. Sometimes, the most complex designs promise high efficiency but demand more investment in time and effort. Reflect on your actual needs before making a choice. A balance between efficiency and ease of use could be crucial for your long-term satisfaction.

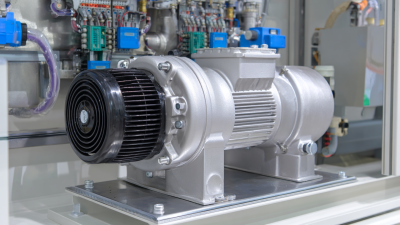

Comparing Different Types of Oil-Free Vacuum Pumps

When selecting an oil-free vacuum pump, exploring different types helps ensure you find the right fit. One popular type is the diaphragm pump. These pumps utilize a flexible diaphragm, creating a seal during operation. They are known for clean operation and minimal maintenance. However, they may not provide the strongest suction for heavy-duty applications.

Another option is the rotary vane vacuum pump. This design uses rotating vanes to create a vacuum. They work well for a range of tasks, from laboratory settings to industrial use. While they are effective, their efficiency can decline over time if not properly maintained.

Regular checks are essential to avoid performance issues.

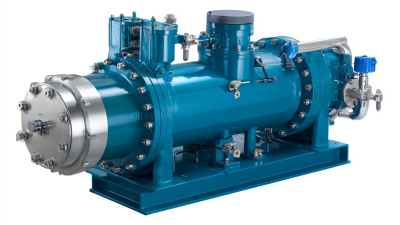

Scroll down to piston pumps, another viable choice. These use a piston mechanism to compress gases. They offer strong suction and are ideal for various applications. However, operating them can be noisy, which might not suit all environments. Understanding these differences is crucial to avoid buying a pump that doesn’t meet your needs.

Evaluating Manufacturer Reputation and Customer Support

When choosing an oil-free vacuum pump, evaluating the manufacturer's reputation is essential. A strong reputation often reflects a commitment to quality. Customers tend to trust manufacturers with positive reviews and a history of reliability. According to a recent industry report, 75% of buyers prioritize reputation when selecting equipment. This statistic highlights how crucial it is to research before making a decision.

Customer support is another vital factor. Quality support can make a significant difference. If problems arise, you need prompt assistance. Review customer feedback to gauge support effectiveness. Some users report long response times from certain manufacturers, which can be frustrating. Prioritize companies that offer various support channels, like chat and phone options.

Tips:

1. Check online forums for unbiased opinions on manufacturers.

2. Look for comprehensive warranties to assess the manufacturer's confidence in their products.

3. A responsive support team can save you time and money in the long run.

Be cautious of manufacturers with inconsistent reviews. It could signal potential issues. An informed decision can lead to long-term satisfaction with your choice of vacuum pump.

Related Posts

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

Exploring the Efficiency of Oil Vacuum Pumps: The Future of Industrial Sustainability

-

Why Air Tech is Revolutionizing the Future of Sustainable Transportation?

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

2026 How to Use Oil Vacuum for Efficient Maintenance and Cleanup?