How to Choose the Right Vacuum Industrial Solutions for Your Business Needs

Choosing the right vacuum industrial solutions is crucial for optimizing efficiency and productivity in various business operations. As companies strive to enhance their processes, the selection of the appropriate vacuum systems becomes a fundamental task that can significantly impact their overall performance. Understanding the different types of vacuum industrial technologies available on the market, alongside the specific needs of your business, is essential for making an informed decision. Factors such as the application environment, the materials being handled, and the scale of operations play a pivotal role in determining the ideal vacuum system. In this guide, we aim to provide a comprehensive overview of the considerations and variables to keep in mind, empowering you to select the vacuum industrial solution that best aligns with your operational requirements and goals.

Understanding Different Types of Industrial Vacuum Solutions Available

When selecting industrial vacuum solutions, it’s essential to understand the various types available in the market and how they align with your business needs. Industrial vacuums can generally be categorized into several types: wet/dry vacuums, high-efficiency particulate air (HEPA) vacuums, and central vacuum systems. According to a report by Grand View Research, the global industrial vacuum cleaner market is expected to reach USD 1.21 billion by 2025, driven by the growing emphasis on maintaining cleanliness in industrial environments.

Wet/dry vacuums offer flexibility for handling both liquid and solid debris, making them ideal for construction sites or manufacturing plants. In contrast, HEPA vacuums are essential in environments requiring stringent air quality control, such as hospitals and pharmaceutical facilities, as they can capture 99.97% of particles that are 0.3 microns or larger. A recent study published in the Journal of Hazardous Materials highlighted that effective dust control using industrial vacuums can reduce workplace respiratory hazards by up to 50%. Meanwhile, central vacuum systems provide convenience and efficiency for larger facilities, enabling easy access to multiple areas without the hassle of transporting equipment. Understanding these distinctions ensures your choice aligns with specific operational requirements and safety standards.

Industrial Vacuum Solutions Comparison

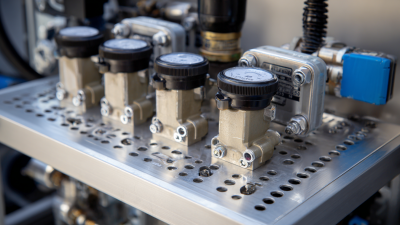

Key Factors to Consider When Selecting an Industrial Vacuum System

Choosing the right industrial vacuum system can significantly impact your operational efficiency and safety. When evaluating options, consider factors such as suction power, filtration efficiency, and adaptability to various materials. According to a report by Grand View Research, the global industrial vacuum market is expected to reach $5.08 billion by 2025, indicating a growing demand for effective vacuum solutions tailored to specific business requirements.

Filtration is another critical aspect; opting for a system with HEPA filters can capture 99.97% of particles larger than 0.3 microns, which is essential in industries handling fine dust, chemicals, and hazardous materials. Moreover, assessing the system's compatibility with existing machinery and workflow can enhance productivity. For example, studies show that businesses incorporating centralized vacuum systems have improved operational efficiency by up to 30%, demonstrating the need for a well-integrated solution that aligns with your work environment and industry regulations.

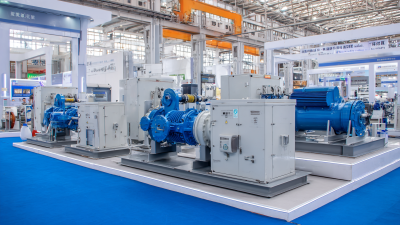

Comparing Performance Metrics of Various Vacuum Types for Businesses

When selecting the appropriate vacuum industrial solutions, it's crucial to evaluate the performance metrics of various vacuum types to align with business requirements. For instance, positive displacement vacuums are renowned for their consistent airflow and ability to handle high levels of dust and debris, making them ideal for heavy industrial applications. In contrast, regenerative blowers offer energy efficiency and a quieter operation, which may be more suitable for environments where noise control is a priority.

Furthermore, application-specific considerations play a vital role in this comparison. For example, suction power, airflow rate, and ultimate vacuum levels must be meticulously analyzed based on the materials being processed. Businesses involved in food processing may prioritize hygiene standards, necessitating vacuum systems that meet stringent sanitation requirements. Conversely, semiconductor manufacturing facilities would focus on achieving ultra-clean environments with specific vacuum levels to avoid contamination. As such, a thorough understanding of these performance metrics enables businesses to make informed choices tailored to their operational needs.

Evaluating Cost-Effectiveness and Efficiency in Vacuum Solutions

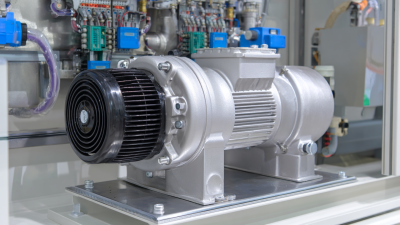

When selecting vacuum industrial solutions for your business, evaluating cost-effectiveness and efficiency is crucial to ensure you make the best investment. The initial cost of a vacuum system can be substantial, but it is essential to consider the total cost of ownership, which includes maintenance, energy consumption, and potential downtime. An efficient vacuum system can significantly reduce operational costs over time by minimizing energy use and maintenance requirements. Therefore, businesses should prioritize systems that offer reliable performance while consuming less power, as this translates to both environmental benefits and lower utility bills.

Efficiency goes beyond just energy savings; it also involves the vacuum system's ability to meet specific operational needs without compromise. Consider the vacuum's performance characteristics, such as its suction capacity and adaptability to various materials, which can influence productivity. Systems designed for quick setup and ease of use can enhance operational efficiency by reducing training time for employees and minimizing interruptions in workflow. An effective evaluation should include a thorough analysis of these factors, enabling businesses to select a vacuum solution that provides optimal performance and cost savings tailored to their unique needs.

Tailoring Vacuum Solutions to Specific Industry Requirements and Challenges

When considering vacuum industrial solutions, it’s crucial to tailor these systems to meet the specific requirements and challenges of your industry. According to a report from the International Vacuum Industry Association, the global vacuum technology market is expected to grow by 10% annually, with sectors like electronics and pharmaceuticals driving demand. Each industry presents unique challenges: for instance, the semiconductor manufacturing sector requires ultra-clean environments to avoid contamination, necessitating advanced vacuum systems that can provide consistent and reliable performance.

Tips for selecting the right vacuum solution include assessing your production environment and specific application needs. For example, if your business is involved in food processing, opt for vacuum systems that comply with food safety standards, ensuring that materials remain uncontaminated. Furthermore, energy efficiency is increasingly becoming a priority; a report from the U.S. Department of Energy indicates that optimized vacuum systems can reduce energy consumption by up to 30%.

Consider conducting a thorough analysis of your operations to identify specific pain points and requirements. Engaging with manufacturers who offer customizable solutions can lead to significant operational improvements. Remember, the right vacuum solution not only boosts productivity but also enhances the overall quality of your product.

Related Posts

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

-

How to Choose the Right Suction Pump for Your Specific Needs

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Exploring Air Vacuum Innovations at the 138th China Import and Export Fair 2025

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs