How to Choose a Custom Manufacturer for Your Business Needs?

Choosing the right custom manufacturer can significantly impact your business's success. According to a report by IBISWorld, the custom manufacturing industry has seen a steady growth of 3.1% annually over the past five years. This growth highlights the increasing demand for specialized products and services. As companies strive for uniqueness, the right manufacturer becomes pivotal.

Expert John Smith, a leader in custom manufacturing, emphasizes, “Selecting a manufacturer is as critical as the product itself.” This statement underscores the importance of aligning your business needs with the capabilities of potential partners. The decision-making process should go beyond price; factors like quality, lead times, and communication play crucial roles.

However, it’s not all straightforward. Many businesses face challenges in assessing capabilities and reputations. An effective partnership hinges on thorough research and clear expectations. The way you approach this task can determine the long-term viability of your products in the market. The stakes are high, and making a mistake can be costly. Investing time in choosing the right custom manufacturer is not just beneficial; it’s essential for sustainable growth.

Understanding Your Business Needs for Custom Manufacturing

Choosing a custom manufacturer starts with understanding your business needs. Assess what products you need and how they fit your market. Identify specific requirements, including materials, dimensions, and designs. Speak with your team to gather insights about production volume and cost constraints. This clarity will guide your search effectively.

Tips: Create a list of must-haves and nice-to-haves. This helps prioritize your requirements. Don’t overlook potential challenges during production. Be open to adjusting your expectations based on capabilities.

Consider the timeline for production. Is there a tight deadline? Ensure the manufacturer can meet it without compromising quality. Communication is crucial. Ask about their response time and support for changes in design. Reflect on previous experiences: what worked well and what didn’t? Use this knowledge to refine your approach when selecting a partner.

Identifying Potential Custom Manufacturers in Your Industry

Identifying potential custom manufacturers in your industry requires careful consideration. Start by researching local and international companies specializing in your product type. Use industry directories, trade shows, and online platforms to compile a list. Evaluate their capabilities, such as material sourcing and production methods. Often, a company’s website may only showcase their best work, which can be misleading.

Consider reaching out to existing clients of these manufacturers. Their experiences can provide insights into reliability and quality. Look for red flags like delayed responses or a lack of transparency. It’s essential to ask detailed questions to understand their processes. Many manufacturers will claim to meet high standards, but actual performance varies. Visits to their facilities can reveal much about their operations.

Engage in direct conversations about your specific needs. Not all manufacturers can adapt to unique requirements. Some may offer cookie-cutter solutions that don’t fit your vision. Having clear specifications is vital, yet flexibility is crucial too. Reflect on what compromises you can accept. Identifying a manufacturer is just the beginning; building a relationship takes time and effort.

Evaluating Manufacturer Capabilities and Expertise

When selecting a custom manufacturer, evaluating their capabilities is crucial. Look beyond basic services. Examine their technology and machinery. Are they using up-to-date equipment? Check if they employ modern manufacturing processes. This can indicate their commitment to quality. It’s vital to visit their facility if possible. Seeing the operation firsthand provides insight into their production scale and efficiency.

Consider their workforce as well. Skilled workers are essential for high-quality products. Ask about training programs. How often do they invest in employee development? A manufacturer focused on continuous improvement is often more reliable. Don’t hesitate to request case studies. Specific examples of past projects reveal expertise in your required area. Be cautious if they hesitate to share.

Lastly, communication matters. A responsive manufacturer can make collaboration smoother. Test their communication style before signing any contracts. Are they clear and helpful? If not, you might face hurdles later. Factor in all these elements when assessing potential partners. It’s about finding a fit for your unique needs.

Evaluating Custom Manufacturer Capabilities

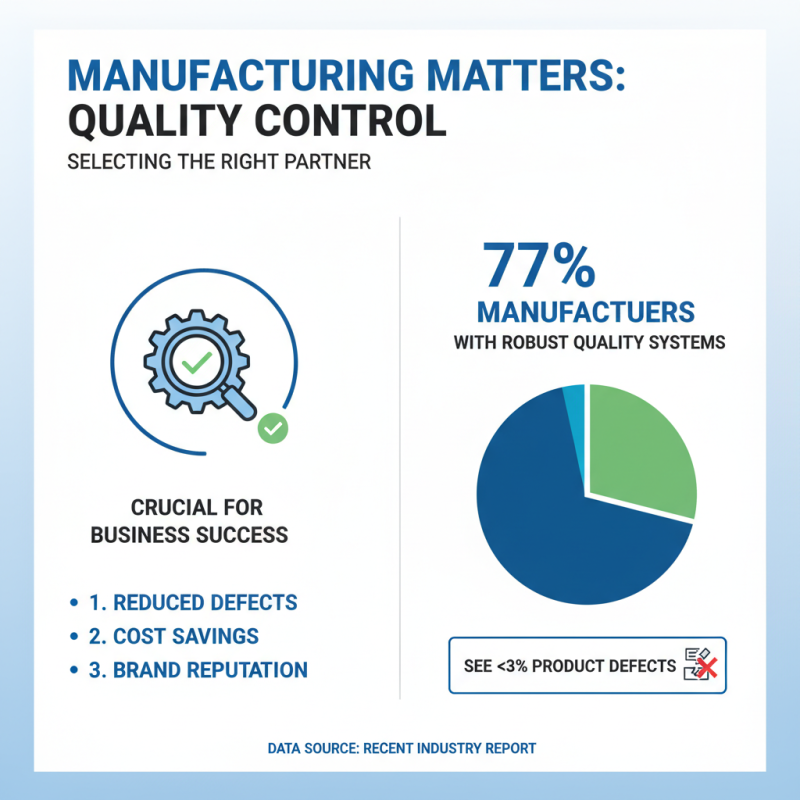

Assessing Quality Control Measures and Standards

Selecting the right custom manufacturer is crucial for your business. Quality control measures are essential in this process. According to a recent industry report, 77% of manufacturers with robust quality systems see less than 3% product defects. This highlights the importance of stringent quality standards in production.

When assessing potential partners, ask about their quality control protocols. Look for certifications like ISO 9001, which indicates adherence to international quality standards. Inspect their testing procedures, including materials sourcing and product inspections. A manufacturer committed to quality will often conduct routine audits and offer transparency in processes.

Tip: Request samples before committing. It offers a firsthand view of their quality. Don’t overlook any deviations; they can signal deeper issues. Also, inquire about their response times if defects occur. This can reveal their dedication to quality service and products. Remember, quality issues can cost you time and money. Make sure your manufacturer prioritizes quality above all else.

Reviewing Cost Structures and Contract Terms for Custom Orders

When choosing a custom manufacturer, cost structures matter greatly. Understand the pricing breakdown clearly. Are there hidden fees? Some manufacturers may add extra costs for design changes. Transparency is key. Request detailed quotes that outline every charge. This makes it easier to compare options.

Contract terms also deserve careful attention. Look for minimum order quantities and lead times. A flexible supplier can adapt to your business's needs. Pay attention to payment terms, too. Some manufacturers require upfront payments, while others offer net terms. Ensure you are comfortable with the conditions in place.

Reflect on your needs. A lower price might not guarantee quality. Sometimes, the cheapest option results in more significant issues later. Balance cost against the quality and reliability you require. Evaluate how contractual obligations may impact your business. A well-structured agreement will protect both parties, avoiding misunderstandings in the future.

How to Choose a Custom Manufacturer for Your Business Needs?

| Manufacturer Type | Cost Structure | Minimum Order Quantity | Lead Time | Contract Terms |

|---|---|---|---|---|

| Injection Molding | Fixed & Variable Costs | 1000 units | 4-6 weeks | Net 30 Days |

| 3D Printing | Pay-per-Print | No minimum | 1-2 weeks | Pre-payment required |

| CNC Machining | Hourly Rate | 500 units | 2-4 weeks | Net 15 Days |

| Sheet Metal Fabrication | Material + Labor Costs | 100 units | 3-5 weeks | Payment upon delivery |

| Textile Manufacturing | Cost per yard | 200 yards | 4-8 weeks | 30% deposit |

Related Posts

-

10 Custom Engineering Tips to Boost Your Project Efficiency by 40% in 2023

-

The Hidden Benefits of Rotary Pumps: Why They Are Essential for Modern Industries

-

Top 2025 Compressor Vacuum Pump Trends and Innovations You Should Know

-

2026 How to Choose the Right Vacuum Pump Manufacturer for Your Needs?

-

Top 10 Blower Pumps for Efficient Air Movement and Optimal Performance

-

How to Choose the Right Oil Vacuum Pump for Your Needs?