2026 Best Vacuum Pump Options for Every Industry Need?

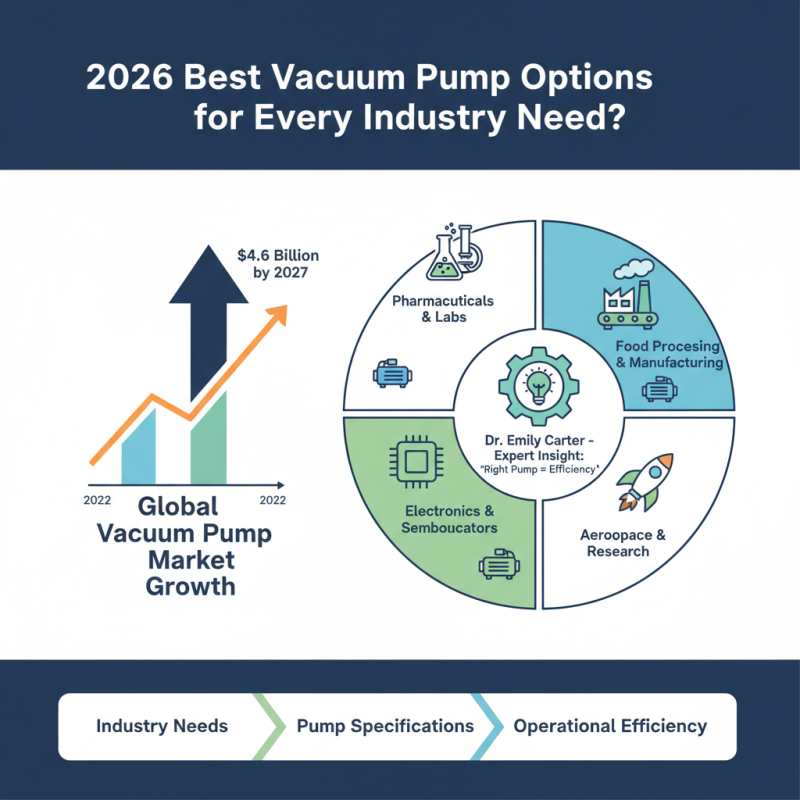

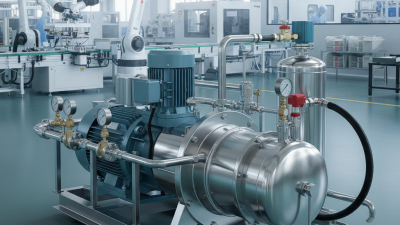

Vacuum pumps play a crucial role across various industries, from pharmaceuticals to food processing. According to a recent market report, the global vacuum pump market is expected to reach $4.6 billion by 2027, growing at a CAGR of 5.2%. This growth highlights the increasing demand for efficient and reliable vacuum solutions.

Dr. Emily Carter, a renowned expert in vacuum technology, emphasizes the importance of selecting the right vacuum pump. She states, "Choosing the correct vacuum pump can drastically improve operational efficiency." Different industries require distinct specifications and features in their vacuum pumps, making it vital to understand these needs.

A mismatch in pump selection can lead to inefficiencies and operational challenges. For instance, a laboratory may require a different pump type compared to a manufacturing setup. This article explores the best vacuum pump options tailored to various industry needs, ensuring you can find the right fit for specific applications. Understanding these dynamics will provide clarity in a complex market.

Best Vacuum Pump Types for Different Industries

When selecting vacuum pumps for different industries, it's essential to understand their unique requirements. For food processing, for example, a positive displacement pump is often ideal. This type effectively removes air from packaging, extending product shelf life. Reports indicate that improper vacuum sealing can lead to spoilage rates of up to 27%, underscoring the need for reliable vacuum systems.

In the pharmaceutical industry, rotary vane pumps are frequently applied. They create strong vacuum conditions essential for processes like freeze-drying. Data shows that over 40% of drugs rely on effective vacuum systems for production. However, maintenance can be challenging, and a failure might halt operations.

For applications in the automotive sector, diaphragm pumps are recommended. They handle corrosive fluids and gases well. Yet, leaks can occur, causing safety and efficiency concerns. Industry studies suggest that improving pump reliability could save manufacturers up to 15% in operational costs annually. It's crucial not to overlook these risks when selecting the appropriate vacuum pump for your specific needs.

2026 Best Vacuum Pump Options for Every Industry Need

| Industry | Pump Type | Application | Vacuum Range (mbar) | Approx. Price ($) |

|---|---|---|---|---|

| Food & Beverage | Rotary Vane Pump | Packaging & Sealing | 1-100 | 1500 |

| Pharmaceutical | Diaphragm Pump | Filling & Mixing | 1-10 | 2000 |

| Laboratory | Piston Pump | Vacuum Filtration | 0.1-10 | 3000 |

| HVAC | Scroll Pump | Refrigeration System Maintenance | 5-50 | 800 |

| Chemical | Liquid Ring Pump | Chemical Processing | 5-100 | 2500 |

Key Features to Consider in Vacuum Pumps

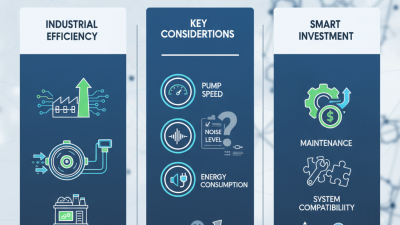

When choosing a vacuum pump, key features are essential. Different industries have varying requirements, and understanding these can make a big difference. According to the latest industry report, about 70% of vacuum pump users prioritize efficiency and reliability. Efficiency can lead to cost savings over time. Reliability is crucial, especially in sectors like pharmaceuticals, where precision is vital.

The materials used in the pump’s construction also matter. Pumps made from stainless steel, for instance, have higher corrosion resistance. This extends their lifespan, making them a long-term investment. Additionally, noise levels are often overlooked. A quieter pump improves workplace comfort. Reportedly, noise reduction in vacuum systems can boost employee productivity by 15%.

Another critical factor is maintenance. Easy-to-maintain pumps require less downtime. Industry studies suggest that over 50% of organizations experience unplanned maintenance. This could indicate a need for better design. Users must evaluate their potential choices carefully. They should consider not just performance but also how easy it is to keep the pump running smoothly. Choices made can significantly influence operational efficiency.

Top Brands and Models of Vacuum Pumps in 2026

In 2026, the vacuum pump market is booming. Various industries require specific solutions. According to a recent industry report, the global vacuum pump market is expected to reach $4.1 billion by 2026, growing at a CAGR of 4.5%. Industries such as pharmaceuticals, food processing, and electronics are major contributors to this growth.

Top models of vacuum pumps cater to diverse applications. For instance, rotary vane pumps are favored in the automotive sector for their efficiency. Meanwhile, diaphragm pumps excel in laboratory settings, providing contamination-free operations. It’s interesting to note that, despite advancements, some old designs still prove reliable. However, many users often don’t fully utilize their capabilities.

Data indicates that energy efficiency is a vital consideration. In recent studies, energy consumption accounted for up to 60% of operational costs. Many companies overlook maintenance schedules, leading to reduced efficiency over time. Ensuring regular maintenance can significantly improve performance. There’s potential for users to rethink strategies and practices, seeking better productivity from their vacuum systems.

Maintenance Tips for Optimal Vacuum Pump Performance

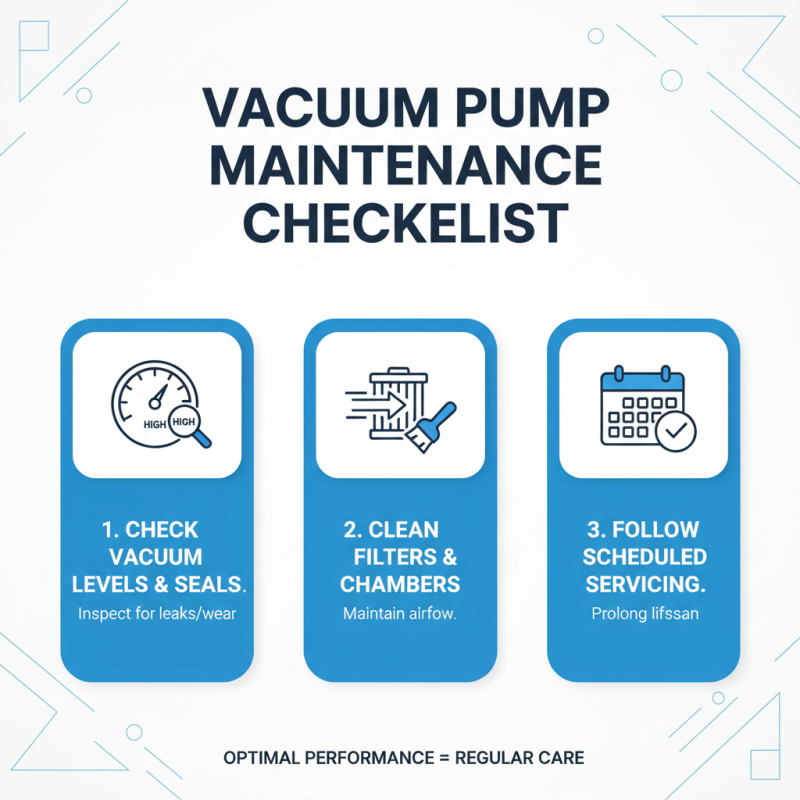

To ensure optimal performance of vacuum pumps, proper maintenance is key. Regularly check vacuum levels and inspect seals for any signs of wear. Damaged seals can lead to leaks, affecting efficiency. Cleaning filters and pump chambers as per the schedule can help maintain airflow and prolong lifespan.

Monitoring oil levels and quality is crucial. If the oil turns cloudy or thick, it’s time to change it. Over time, oil can become contaminated, leading to pump damage. Listening for unusual sounds is also important. Strange noises could indicate internal wear. Though maintenance might seem tedious, neglect can lead to expensive repairs.

Sometimes, operators overlook simple tasks. Forgetting to check vents can restrict airflow. Inadequate ventilation can cause overheating, reducing efficiency. Keep a log of maintenance tasks to hold everyone accountable. Reflecting on past maintenance can guide future actions and improve overall reliability.

Applications of Vacuum Pumps Across Various Sectors

Vacuum pumps are essential across various industries. They create a vacuum environment for many applications. In the food industry, they help with packaging. Removing air extends shelf life. This method preserves freshness while ensuring safety. That’s crucial for consumer trust.

In the pharmaceutical sector, vacuum pumps assist in drug manufacturing. They streamline processes like freeze-drying and distillation. However, even small faults can lead to contamination. This highlights the need for detailed maintenance and checks. Current technologies often demand up-to-date knowledge to operate effectively.

Moreover, vacuum pumps are vital in the automotive industry. They aid in assembling parts and testing. Yet, there can be limits to their effectiveness, especially in high-demand scenarios. Adjustments are sometimes needed to meet specific requirements. Learning from these experiences is key for improvement.

2026 Vacuum Pump Applications Across Various Industries

This chart illustrates the distribution of vacuum pump usage across various industries in 2026. Manufacturing leads with 120,000 units, followed by Food Processing and Packaging, highlighting the critical role of vacuum pumps in diverse applications.

Related Posts

-

Top Benefits of Using a Dry Vacuum Pump for Your Industrial Applications

-

Top Factors to Consider When Choosing a High Vacuum Pump for Your Needs

-

2026 Best Dry Vacuum Pumps for Efficient Industrial Applications?

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

-

How to Choose the Right Oil Vacuum Pump for Your Needs?