Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals

In the realm of HVAC systems, understanding the science behind AC vacuum pumps is critical for professionals seeking to optimize performance and efficiency. AC vacuum pumps play a pivotal role in the refrigeration cycle, ensuring the system operates free of moisture and air, which can hinder efficiency and lead to costly repairs. According to a report by the U.S. Department of Energy, systems that are properly evacuated with high-quality vacuum pumps can improve energy efficiency by up to 30%. Moreover, the HVAC industry continues to grow, with a projected market size reaching $155 billion by 2026, underscoring the necessity for HVAC professionals to deepen their knowledge regarding the operational integrity provided by AC vacuum pumps. This understanding not only supports improved service delivery but also aligns with the industry's push towards sustainability and energy efficiency.

How AC Vacuum Pumps Function: A Comprehensive Overview for HVAC Technicians

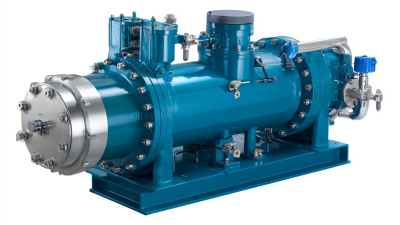

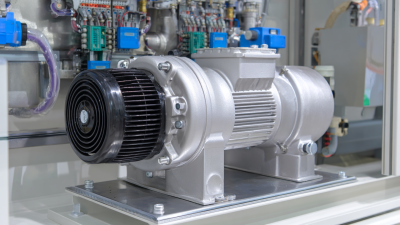

AC vacuum pumps are critical tools for HVAC technicians, enabling the removal of moisture and air from refrigerant systems. These pumps operate by creating a low-pressure environment, which facilitates the extraction of unwanted gases and fluids. Understanding how these vacuum pumps function helps technicians perform efficient evacuations and ensures the longevity of the HVAC systems they service. Key components such as the motor, pump body, and exhaust port work in unison to achieve optimal vacuum levels, making the selection of the right pump crucial for specific applications.

Tips: When selecting an AC vacuum pump, it’s essential to consider factors such as pump capacity and oil type. A double-stage pump is often recommended for professional use, as it can achieve a deeper vacuum in a shorter amount of time. Additionally, always check the oil level and quality before use to ensure maximum efficiency and prevent potential damage to the pump.

To effectively use an AC vacuum pump, technicians should be familiar with proper connection setups, including the use of proper vacuum hoses and fittings to avoid leaks. Ensuring that the system is well-prepared before attaching the pump will enhance the evacuation process. Regular maintenance and calibration of the vacuum pump not only prolong its lifespan but also ensures consistent performance during each job.

Identifying Key Components of Vacuum Pumps and Their Roles in HVAC Systems

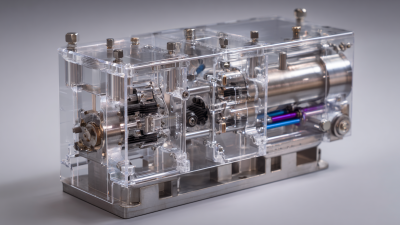

Vacuum pumps are critical components in HVAC systems, ensuring the efficient removal of moisture and air from refrigerant lines. By understanding the key components of these pumps, HVAC professionals can optimize system performance and enhance reliability. The primary parts of a vacuum pump include the motor, vacuum chamber, and exhaust valve. The motor drives the pump, while the vacuum chamber acts as a reservoir where the air and moisture are evacuated. The exhaust valve releases any trapped gases, allowing the system to maintain a consistent vacuum level.

Vacuum pumps are critical components in HVAC systems, ensuring the efficient removal of moisture and air from refrigerant lines. By understanding the key components of these pumps, HVAC professionals can optimize system performance and enhance reliability. The primary parts of a vacuum pump include the motor, vacuum chamber, and exhaust valve. The motor drives the pump, while the vacuum chamber acts as a reservoir where the air and moisture are evacuated. The exhaust valve releases any trapped gases, allowing the system to maintain a consistent vacuum level.

One vital metric to consider is the pump's ultimate vacuum level, which is often measured in microns. A high-quality vacuum pump can achieve levels below 50 microns, thereby ensuring that the system is sufficiently evacuated. According to a report by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), achieving a proper vacuum is crucial for system efficiency, impacting energy consumption and operational longevity.

Tips: When selecting a vacuum pump, look for models that provide a digital gauge to monitor vacuum levels accurately. Additionally, ensure routine maintenance on the pump to prevent performance issues and maintain optimal operation. Always verify the ultimate vacuum level before sealing the system to guarantee full evacuation.

Step-by-Step Guide to Properly Operating AC Vacuum Pumps in HVAC Applications

Operating AC vacuum pumps in HVAC applications requires a precise understanding of the equipment and the processes involved. First, ensure all necessary safety precautions are followed. Before starting the pump, connect it to the service port of the HVAC system, ensuring all valves are closed to prevent refrigerant leakage. It's crucial to monitor the gauges closely during operation, as they provide real-time feedback on system pressure and help identify any potential issues.

Once the vacuum pump is connected, turn it on and allow it to run until the pressure reaches an appropriate vacuum level, typically between 500 to 750 microns. This step is critical to remove moisture and non-condensables from the system. After achieving the desired vacuum, turn off the pump and isolate it from the system by closing the service valves. Finally, wait for about 15 minutes to verify that the vacuum holds steady. If the pressure rises, it may indicate a leak that needs to be addressed before proceeding with system refrigerant charging. Proper operation and maintenance of AC vacuum pumps not only extend their lifespan but also ensure optimal performance of HVAC systems.

Common Mistakes to Avoid When Using Vacuum Pumps in HVAC Service

When using vacuum pumps in HVAC service, professionals often make several common mistakes that can compromise their work. One prevalent error is failing to achieve the proper vacuum level. HVAC technicians must ensure that they create a deep vacuum to remove moisture and contaminants effectively from the system. This is crucial because any residual moisture can lead to compressor failure and reduced system efficiency. Using an improper gauge or skipping the vacuum verification step can result in inadequate performance.

Another frequent pitfall is neglecting maintenance and proper handling of the vacuum pump itself. Many professionals overlook the importance of regularly checking the pump oil and replacing it as needed. Contaminated oil can impact the pump's efficiency and lead to operational issues. Additionally, technicians sometimes forget to ensure that all connections are airtight. Any leaks in the system can introduce air into the vacuum, undermining the entire evacuation process. By being mindful of these mistakes, HVAC professionals can enhance their service quality and extend the life of the equipment they work on.

Maintenance Best Practices for Prolonging the Life of AC Vacuum Pumps in HVAC Work

Understanding the maintenance best practices for AC vacuum pumps is crucial for HVAC professionals looking to enhance their operational efficiency and extend equipment lifespan. Regular maintenance not only prevents unexpected breakdowns but also ensures optimal performance. According to a report by the Air Conditioning, Heating, and Refrigeration Institute (AHRI), well-maintained vacuum pumps can achieve a lifespan increase of up to 50%, providing significant cost savings in the long run.

One key practice involves regular oil changes and monitoring oil quality. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlights that contaminated oil can lead to overheating and mechanical failure. Additionally, ensuring that the pump is operating in a clean environment and using high-quality filters can significantly reduce wear and tear, enhancing reliability. Furthermore, proper storage of the pumps when not in use can prevent rust and corrosion, contributing to an extended lifespan and sustained performance efficiency.

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals

| Parameter | Description | Best Practice |

|---|---|---|

| Pump Type | Different types of AC vacuum pumps (e.g., rotary vane, diaphragm) | Choose the appropriate type based on application needs |

| Oil Level | Ensuring proper oil level for rotary vacuum pumps | Regularly check and maintain oil levels |

| Maintenance Frequency | How often to service the vacuum pump | Perform maintenance every 6 months or as needed |

| Filter Condition | Checking the condition of air filters | Replace filters if dirty or clogged |

| Operating Temperature | Ideal temperature range for optimal performance | Monitor temperature; avoid extremes |

| Vacuum Level | Achieving the required vacuum level for HVAC systems | Regularly test vacuum levels with a gauge |

| Leak Detection | Checking for leaks in the system | Use electronic leak detectors regularly |

| Training | Knowledge of pump operation and safety | Ensure ongoing training for all personnel |

Related Posts

-

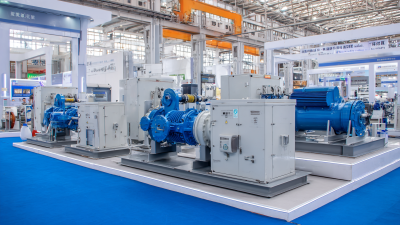

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Exploring Air Vacuum Innovations at the 138th Canton Fair 2025