2026 Top Blower Manufacturer Trends and Innovations to Watch

In the rapidly evolving landscape of the blower manufacturer industry, 2026 promises to bring significant trends and innovations. John Smith, a recognized expert in blower technologies, emphasizes the need for adaptation: "Those who fail to innovate, fall behind." This statement underscores the importance of embracing change in today's market.

Understanding upcoming trends is crucial for manufacturers. Energy efficiency is at the forefront of design improvements. Innovations in materials are also evolving, allowing for lighter and more durable products. Additionally, automation and smart technology integrations are gaining traction. These elements are reshaping how businesses operate and interact with their clients.

However, challenges remain. Not every manufacturer adapts quickly, leading to gaps in product offerings. Some companies struggle with the implementation of new technologies due to costs or resistance to change. The industry must address these issues to thrive. Continuous improvement and innovative thinking will be fundamental for any blower manufacturer aiming for success in 2026 and beyond.

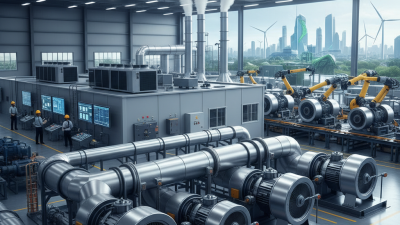

Emerging Technologies Driving Blower Manufacturing Innovations in 2026

In 2026, the blower manufacturing industry is on the brink of significant innovation. Emerging technologies are reshaping the landscape. Advanced materials will make blowers lighter and more efficient. This shift allows for better energy use and enhanced performance. New designs will focus on reducing noise levels, making operations smoother in sensitive environments.

Digital transformation is key. IoT integration will enable real-time monitoring of blower performance. Manufacturers can analyze data to predict failures before they occur. However, this shift demands new skills from the workforce. Training is essential for adapting to these changes. Additionally, smart technology raises cybersecurity concerns that need attention.

Sustainability will also drive innovation. Biodegradable materials are in demand, but sourcing them presents challenges. Balancing cost and eco-friendliness is tricky. Innovations in blowers must account for these factors. Companies may struggle at the intersection of performance and green technologies. Continuous improvement is crucial as the industry evolves.

Sustainability Trends Impacting Blower Design and Production

The future of blower manufacturing is intertwined with sustainability. As industries strive to reduce their carbon footprints, blower designs are evolving. Manufacturers are now focusing on energy-efficient technologies that consume less power. This shift is essential for meeting both regulatory demands and customer expectations.

Choosing sustainable materials is another way manufacturers are innovating. Many are experimenting with biodegradable plastics and recyclable metals. These materials may not always meet performance standards perfectly. However, the long-term benefits can outweigh these initial imperfections.

**Tip:** Consider the type of material your blower is made from. Look for options that emphasize sustainability without sacrificing efficiency.

Furthermore, companies are exploring smarter manufacturing processes. Automation and AI are making production faster and more efficient. Yet, not all plants are fully integrated with these technologies. Many still rely on outdated methods that hinder progress.

**Tip:** Evaluate your production methods regularly. Identify areas where sustainability can be prioritized without compromising quality.

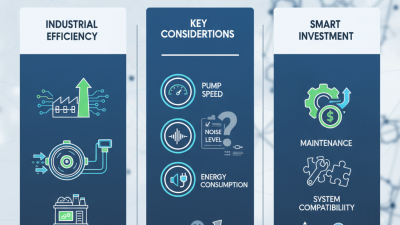

Market Demand Shifts and How They Influence Blower Features

As the demand for blowers evolves, manufacturers must adapt to shifting market needs. In recent years, industries have focused on energy efficiency. This has led to innovations in blower design. Many systems now incorporate smart technology. Such features monitor performance in real-time, ensuring optimal operation.

Another significant trend is the emphasis on sustainability. Green technologies are becoming essential in product development. Customers prefer blowers that minimize environmental impact. This transition is challenging for some manufacturers. Many are still relying on older technology. The balance between innovation and existing capabilities requires careful planning.

Finally, customization is key. Different industries have unique requirements. A one-size-fits-all approach is often insufficient. Manufacturers are beginning to offer tailored solutions. However, this creates complexity in production schedules. Each change requires testing and validation. Companies must reflect on their current processes to remain competitive.

2026 Blower Manufacturer Trends and Innovations

Key Players and Their Strategic Moves in the Blower Industry

As we navigate through 2026, the blower industry is undergoing significant changes driven by key players. These companies are investing heavily in innovative technologies. This includes the rise of smart blowers that utilize IoT. Such devices allow for remote monitoring and control. They aim to enhance operational efficiency and reduce energy consumption.

Collaboration among industry leaders is increasingly common. They are forming strategic partnerships to innovate faster. This means sharing research and development resources. The goal is to create more efficient, quieter, and environmentally friendly blowers. However, not all partnerships yield the intended results. Sometimes, misaligned objectives hinder progress.

Moreover, sustainability continues to be a major focus. Key players are exploring eco-friendly materials and energy-efficient designs. This shift is reshaping manufacturing processes. Yet, it raises questions about overall costs and market viability. As the industry evolves, challenges will persist. Companies need to remain agile and adaptive to overcome these hurdles.

2026 Top Blower Manufacturer Trends and Innovations to Watch - Key Players and Their Strategic Moves in the Blower Industry

| Category | Trend/Innovation | Impact | Strategic Move |

|---|---|---|---|

| Energy Efficiency | Development of variable speed blowers | Reduces energy consumption significantly | Investment in R&D for smarter controls |

| Sustainability | Use of recyclable materials in blower construction | Lower carbon footprint during production | Partnerships with eco-friendly suppliers |

| Smart Technology | Integration of IoT for remote monitoring | Improved operational efficiency and maintenance | Acquisition of tech startups |

| Customization | Modular blower designs for specific industries | Increased market adaptability | Expanding service networks |

| Health and Safety | Development of noise-reducing blower technology | Enhanced workplace safety and comfort | Campaigns to raise awareness of noise pollution |

Future Challenges and Opportunities Facing Blower Manufacturers in 2026

The blower manufacturing industry faces significant challenges in 2026. Environmental regulations are stricter than ever, pushing for sustainable practices. Manufacturers may struggle to adapt to these requirements quickly. Investment in greener technologies can be costly and time-consuming. This places additional pressure on companies to innovate while maintaining profitability.

At the same time, new opportunities emerge. The demand for efficient airflow solutions is rising in sectors like HVAC and industrial applications. Businesses must rethink their strategies to capture this market. Emphasizing energy efficiency in designs can attract eco-conscious customers. Collaboration with technology partners can yield advanced materials and smart features, enhancing performance.

However, adaptation requires introspection. Are manufacturers listening to their customers? Creating tailored solutions is vital. Some may fall into the trap of one-size-fits-all products. They must focus on unique customer needs and feedback. Continuous improvement and flexibility could be the key to thriving in this evolving landscape.

Related Posts

-

What is a Blower Manufacturer? Understanding Their Role and Importance in Industry

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

-

Understanding Regenerative Blowers: Types, Applications, and Benefits

-

2026 How to Leverage Air Tech for Sustainable Innovation?

-

Revolutionizing Industries with Tailored Custom Engineering Solutions

-

2026 Best Dry Vacuum Pumps for Efficient Industrial Applications?